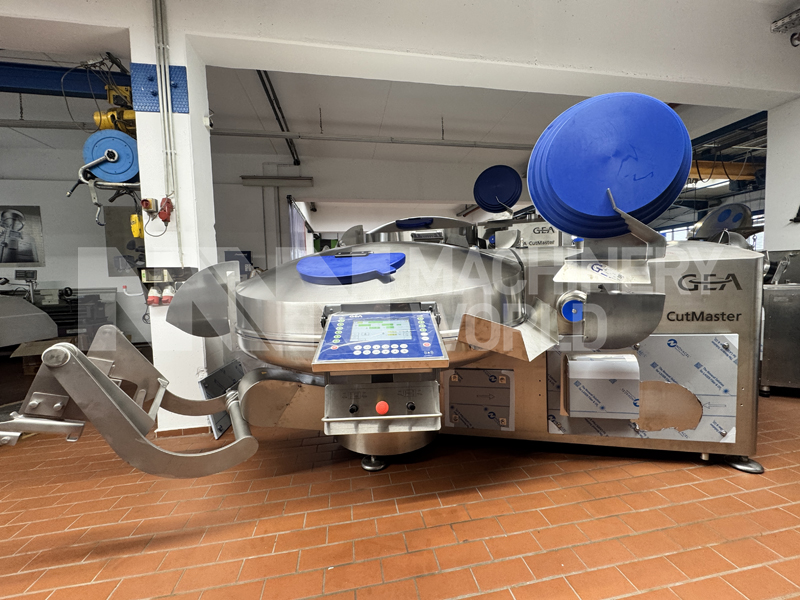

Description

This is a used ROKK CCM200 Universal Vacuum Capable process high shear cutter mixer. These Universal Multi-functional Vacuum Process Cutters-Mixers (CCM – Cooker Cooler Mixer) can be used for a wide range of applications, including the production of processed cheese, dressings, sauces, baby food, confectionery fillings, almond paste, mayonnaise, ketchup etc. They are designed to perform multiple operations such as mixing, emulsifying, homogenizing, cooking and heating through direct steam injection, heating or cooling via an external double jacket, particle size reduction, vacuum cooking, and deaeration using a vacuum pump. Currently held in stock, this ROKK CCM200 Universal Vacuum Mixer is available for immediate sale.

Specification

- Brand: ROKK Processing, UK

- Model: CCM200

- Function: Universal mixing cooker

- Approx Bowl Internal Volume: 200 liters

- Year of Manufacture: 2022

- Max Product Working Capacity: Approx 170 liters/ batch

- Batch Processing Time: Approx 8-12 minutes (Varies depending on type of product & process)

- Max Processing Temperature: 95 deg C

- Hydraulic Tilting Assembly

- Hydraulic Opening & Closing of Lid

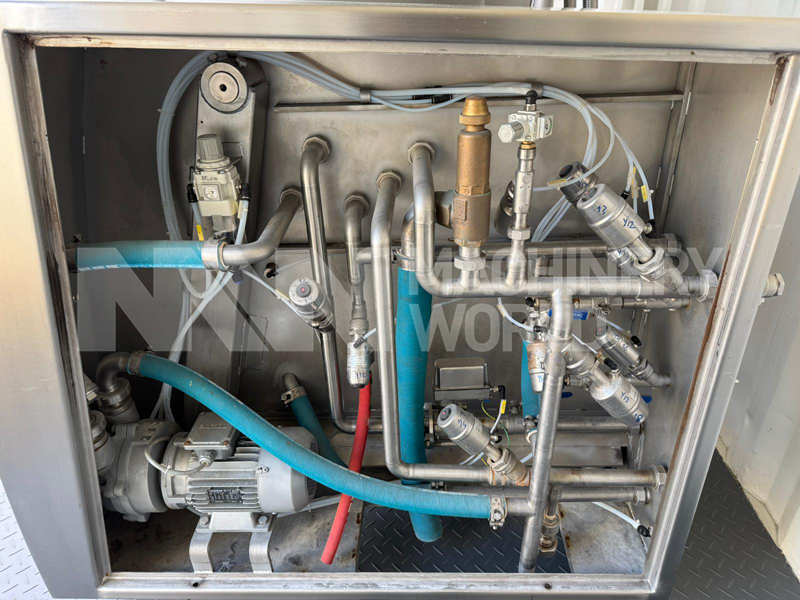

- Direct Steam Injection

- Number of Steam Injection Nozzles: 3x Direct Steam Injection Nozzles

- External Double Jacket for Heating [or] cooling

- Double Jacket Working Pressure: 2 Bar

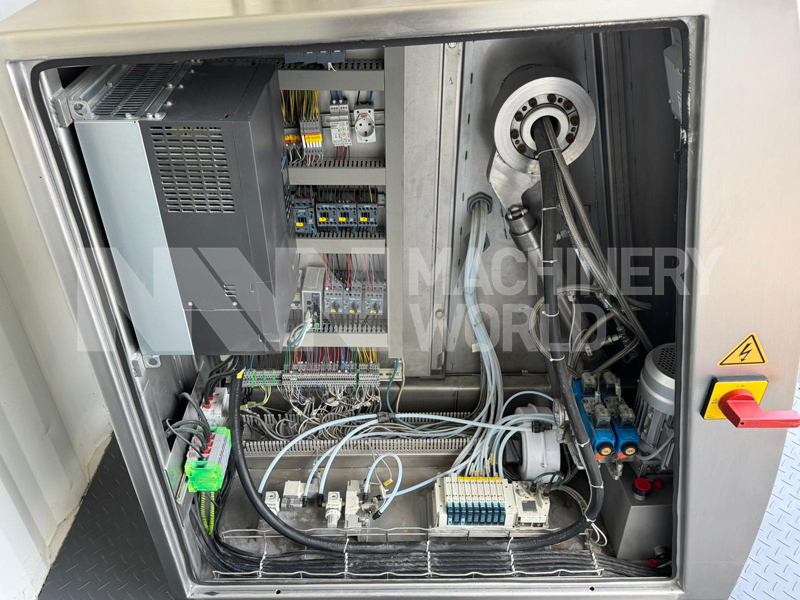

- Vacuum Rated with In-built Vacuum Pump

- Vacuum Pump Motor: 2.2kw, 3-Ph, 380V

- Pneumatic Flushed Discharge Valve

- PLC with Touch Screen HDMI Panel

- Main Bottom Drive Motor: 45kw 3-Ph, 380V

- Bowl Cutter: 3 Knives

- Bottom Cutter Speed: 0 to 3000 RPM (Max)

- Frequency Controlled Inverter for main Motor (Precise Speed Control)

- Side & Top Scrapper: Top Mounted

- Side & Top Scraper Motor: 1.5kw, 3-Ph, 380V

- See ‘Technical Doc’ link for ROKK Brochure.

Features

- Short Batch Time

- Energy Efficient

- Easy Integration into existing Production Line

- PLC Controlled with Recipe Management

- Configurable for many different product applications

- Complete product emptying capability (Minimal Product Losses)

- Precise Speed Control via Frequency Controlled Inverter

Download Technical Doc

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn