Description

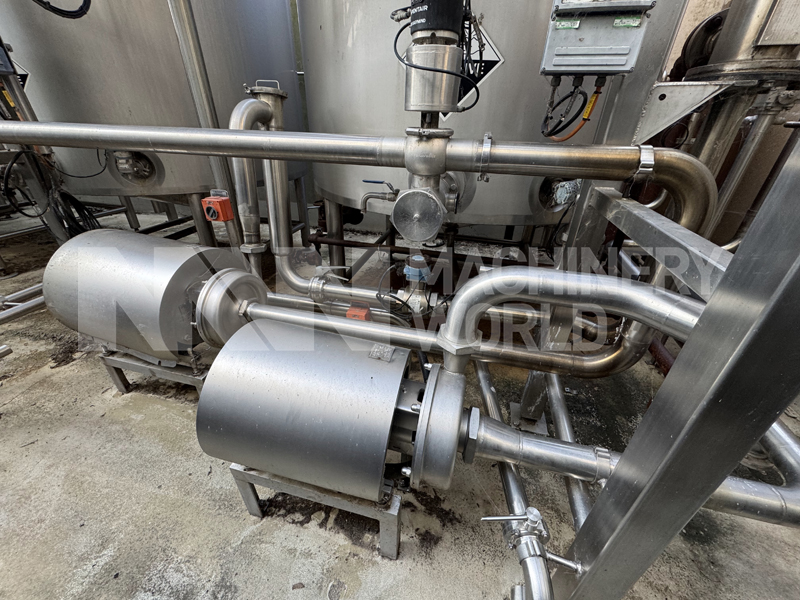

The used GEA 4-Tank Automatic CIP System is a high-capacity, single-channel Clean-In-Place plant designed for efficient, fully automated cleaning of dairy and food-processing lines, pasteurisers, tanks, fillers, and transfer pipework. Rated for approximately 40,000 LPH circulation flow, this industrial CIP unit is powered by Alfa Laval LKH 45 stainless-steel centrifugal pumps (7.5 kW, 145 mm impellers) delivering reliable cleaning velocities to ensure hygienic compliance and effective soil removal across large process circuits. The system comprises three stainless steel CIP tanks (each approx. 3,000 litres) configured for hot water, caustic detergent, and rinse or recovery solutions, allowing full wash sequence automation including pre-rinse, caustic wash, intermediate rinse, sterilisation, and final rinse cycles. The used CIP plant remains installed on site and is sold as-is, non-operational due to full factory closure, representing a cost-effective opportunity for dismantling and relocation for refurbishment or recommissioning.

Specification

- Make: GEA Process, Australia

- Model: Single Channel CIP Unit

- Function: Automatic Clean In Place System (CIP)

- Year of Build: 2005

- Flow Rate: Approx 40,000 LPH

- Type: 3-Tank & 1-Channel System

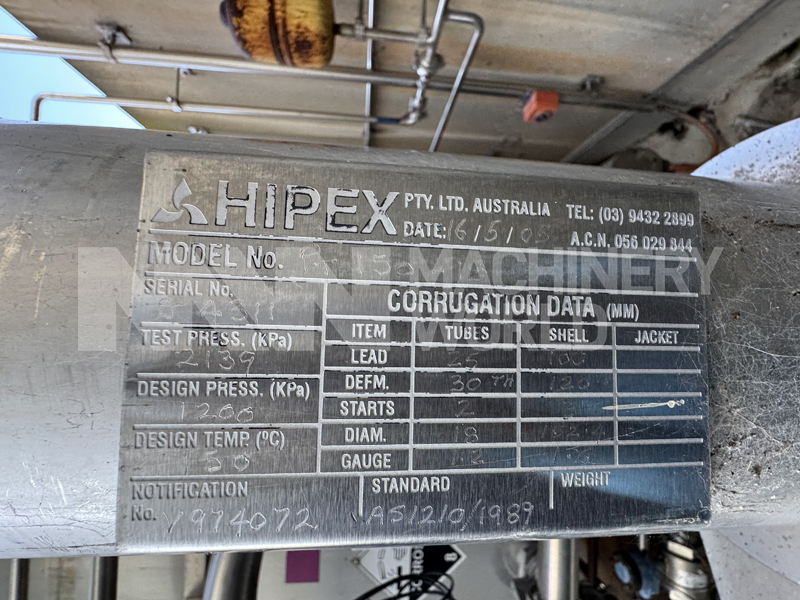

- Heat Exchanger Type: Tubular (Shell-In-Tube)

Tanks:

- Detergent Tank: Approx 3,000 Ltr, Insulated & Stainless Steel Construction.

- Acid Tank: Approx 3,000 Ltr, Insulated & Stainless Steel Construction.

- Recovery Tank: Approx 3,000 Ltr, Insulated & Stainless Steel Construction.

- Fresh Water Tank: Approx 3,000 Ltr & Stainless Steel Construction.

- Includes Top Access Gantry & Walkway

- Top Manway

Pumps:

- Approx 40,000 LPH & 7.5kw Alfa Laval LKH45 Delivery Pump with 148mm Impeller

- Caustic Recirculation Pump

Components Included:

- Sudmo Pneumatic Actuated Butterfly Valves with Feedback

- Various Sensors

- Flow Meters

- Tubular Heat Exchanger

- Inline Filter on the Delivery Line

- Samson Steam Regulating Valve

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn