Description

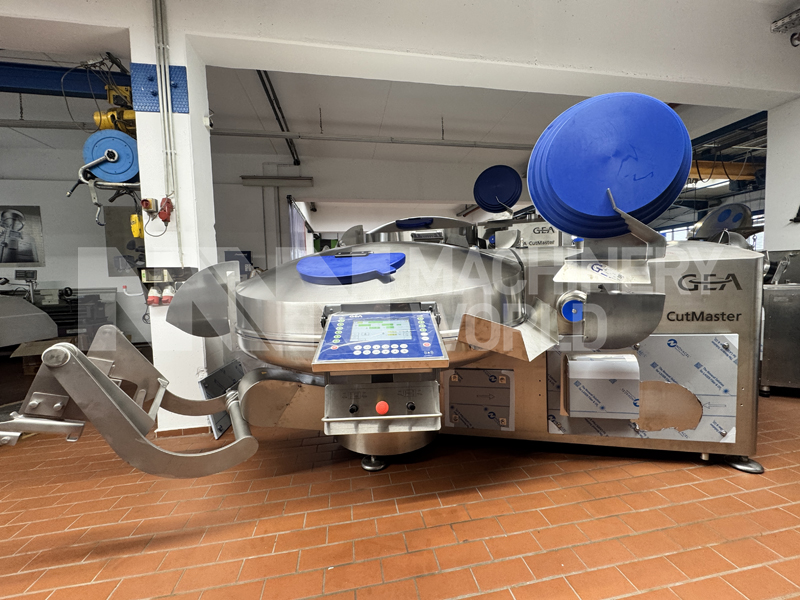

This used and fully rebuilt GEA CutMaster 500V is a premium solution for meat processors seeking vacuum emulsifying, high-speed chopping, and advanced process control in one robust machine. Professionally rebuilt with many new wearable components, a brand-new electrical cabinet, and a new PLC-based control panel with frequency inverter, this machine offers performance comparable to new equipment.

Advanced Features & Equipment

This vacuum capable industrial Bowl Cutter is engineered for high-performance on products such as Sausage, Emulsified products, Pâté, and Processed Meat applications.

- TopCut Knife Head

- Stainless Steel Bowl (Polished)

- Variable Bowl Drive

- Stainless Steel Knife Shaft

- GEA’s Patented Knife Shaft Sealing

- Automatic Knife Shaft Greasing

- Stainless Steel Vacuum Lid

- Closed Stainless Steel Enclosures

- Electrical Cabinet Integrated into Machine Frame

- Automatic Shut-off for Time, Temperature & Bowl Revolutions

- Loading Device for 200L Trolley

- Hydraulic Unloader Arm with Wheel

- Product Discharge Chute

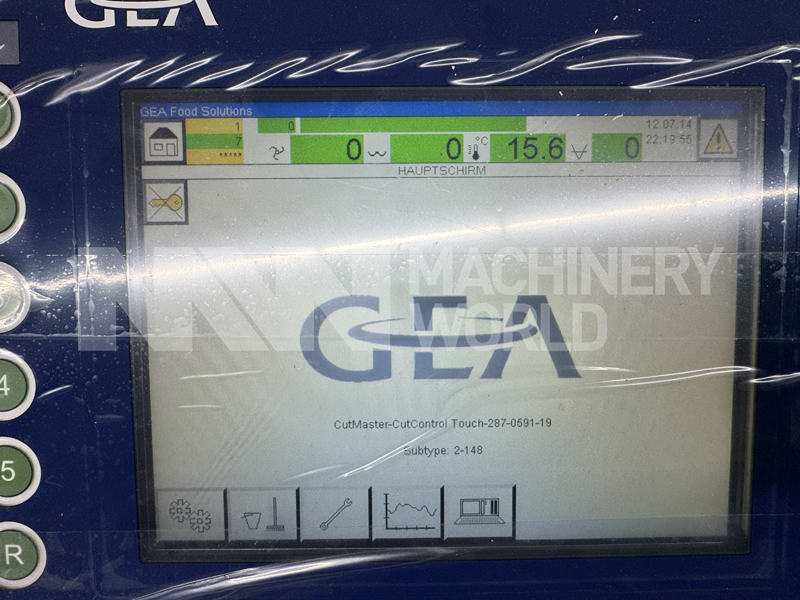

- Fully Integrated PLC + External HMI

- Frequency Inverter for Variable Knife Speed Control

- LN2 Injection System: LN2 injection Available

- Actuated Exhaust Valve & Duct

- Ideal for Cryogenic Processing & Temperature Sensitive Emulsions

Specification

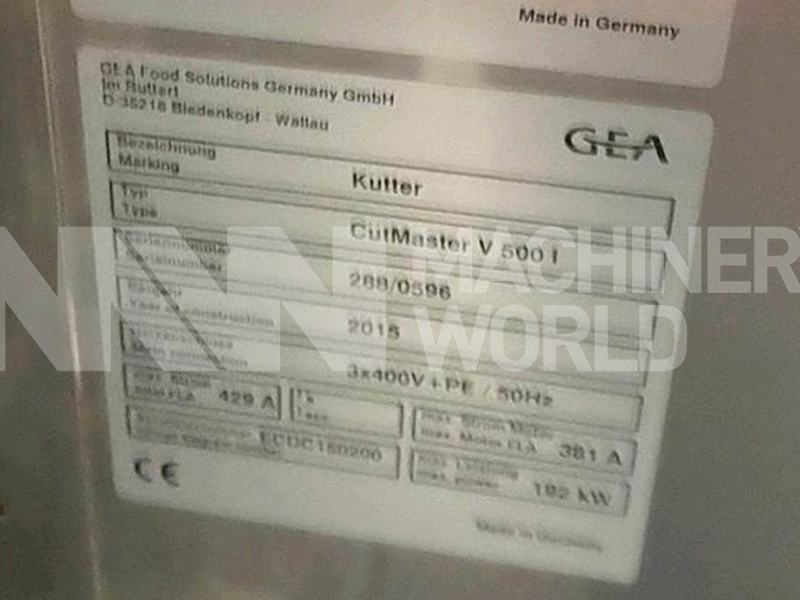

- Make: GEA Food Solutions Germany GmbH

- Type: CutMaster V500L

- Function: Vacuum Capable Bowl Cutter Chopper with LN2 Injection

- Marking: Kutter

- Serial Number: 288/0596

- Volume: 500L

- Fully Rebuilt – 2026

- Total Power: 192kw, 437A, 400V, 3-Ph

- Knife Speed Range: 60 – 3,600 RPM (Variable Speed via Inverter)

- Control Panel: Fully Integrated with PLC and Frequency Inverters

- Control System: GEA Cut Control Touch

- Vacuum System: Liquid Ring Vacuum Pump

- LN2 Connection: Provided (Valve Customer Supplied)

- Water Dosage System: Integrated

- Operator Language: English (Including many other languages)

- Documentation: English (Digital Copy)

Full Professional Refurbishment – Major Upgrades Included

This fully rebuilt GEA CutMaster 500V with Vacuum & LN2 Injection has undergone extensive refurbishment, including the following:

- Mechanical & Structural:

- Newly Painted Machine Frame Housing

- Refurbished Main DC Drives

- New Knife Shaft

- New Bearings

- New Sealing & Gaskets

- New Unloading Disc

- New Belt Drive

- New Shafts & Bolts

- New External Side Panels

- New Fan for Main Drive

- Hydraulic System:

- New Hydraulic Power Pack

- New Hydraulic Cylinders

- New Hydraulic Lines

- New Hydraulic Drive for Unloader

- Electrical & Controls (Major Upgrade):

- New Electrical Cabinet

- New Electrical Wiring

- New Operating Panel

- New Sensors & Switches

- New PLC & Control System

- New Frequency Inverter for Precise Variable Knife Speed

- New Integrated GEA Cut Control HMI

- Lubrication System:

- New Central Lubrication System

- New Lubrication Lines

- Vacuum System:

- New Liquid Ring Vacuum Pump

Shipping

Need help with dairy machinery transportation?

Every month we export machinery to customers all over the world.

Offering competitive prices for air, sea or road freight, we can crate machinery and process all export documents to ensure the process is quick and stress free.

To enquire about shipping, just give us a call on +44(0) 1455 220 179

Spares

Need spares for this machine?

Parts Station stocks a host of spare parts for dairy and ice cream machinery.

With international shipping and door-to-door courier services, Parts Station can supply them quickly before any major disruption occurs. Click below to go to the site.

Have a machine like this to sell?

We make quick decisions and pay the best prices in cash for good quality, used dairy and food processing machinery, from single machines to complete plants.

To sell your machinery, just give us a call on +44(0) 1455 220 179 or

email us

Reviews

To read or send us your own review of our products and services, please click below.

Read our reviews

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn