Description

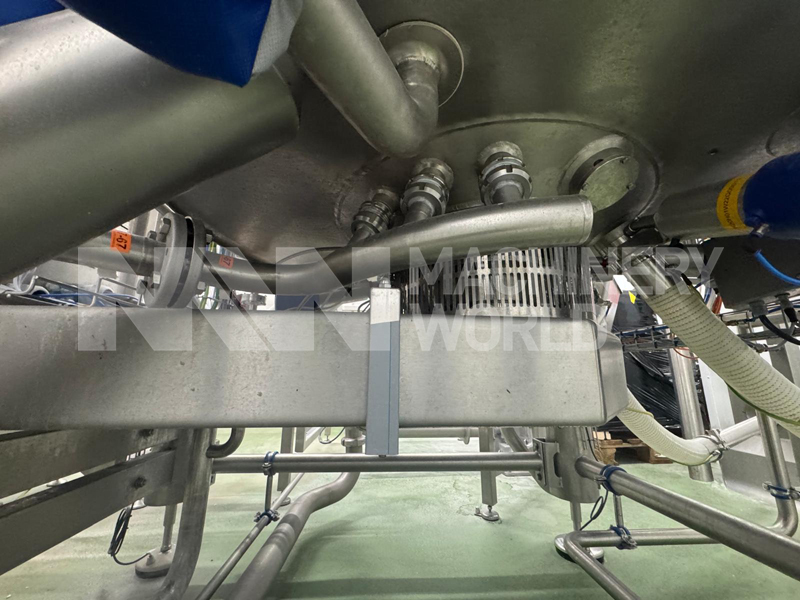

This complete Tetra Pak processing line features a 1,500L Tetra Pak Scanima High Shear Mixer B300-1500VAA equipped with direct steam injection, vacuum capability, and dual counter-rotating agitators for Sauces, Ketchup, Processed Cheese, Analog Cheese, Plant-based Vegan Cheese, Dairy, Fruit Concentrates and prepared food production. Designed for maximum flexibility, this mixer allows cooking, mixing, heating using direct steam injection and cooling via external double jacket in a single vessel, enabling high-quality food products. The plant also includes a dry ingredient Feed Hopper, Euro Bin Tipper, Positive Displacement Screw Pumps got finished product, 500L jacketed product tank, Tetra Pak Plate Heat Exchanger Pasteuriser, Tetra Pak 200-bar High Pressure Piston Homogeniser, plus a 2,450L finished product tank for downstream storage. Also included are various Tetra Pak ThinkTop Valves, Endress & Hauser Flowmeters and automation components ensures hygienic and reliable processing, all coordinated by an integrated control panel with inverters. This turnkey Tetra Pak system delivers efficient, high-shear mixing, precision thermal processing, and consistent finished product quality for modern food and beverage manufacturing. Please note: the attached Technical Doc is provided for reference only; the specifications of the actual equipment offered may vary.

Specification

Tetra Pak Scanima High Shear Batch Mixer

- Make: Tetra Pak, Denmark

- Type: Tetra Pak High Shear Mixer B300-1500VAA (Scanima Mixer)

- Function: Batch High Shear Mixer with Direct Steam Injection & Control Rotating Mixer

- Serial Number: T5845707474

- Year of Manufacture: 2023

- Working Volume: 1,500 Ltr

- Nominal Mixing Capacity: Approx 6,400 kg per hour (Varies depending on the type of product being mixed)

- Net Internal Volume: 2,146 Ltr

- Vessel Design Temperature: 100 deg C

- Vessel Design Pressure: -1 (Full Vac)

- Jacket Design Temperature: 150 deg C

- Jacket Design Pressure: 4 Bar

- Mixers:

- Bottom Entry Turbo High Shear Mixer – 2940 RPM 50kw/3-ph Motor

- Top Entry Scraped Surface Contra-Rotating Mixer

- Vacuum: Comes with Inbuilt Fully Integrated 5.5kw Vacuum Pump

- Nominal Steam Consumption: Approx 750 kg per hour

- Nominal Cooling Water Flow Rate: Approx 10,000 LPH

- Service Water Consumption: 225 LPH

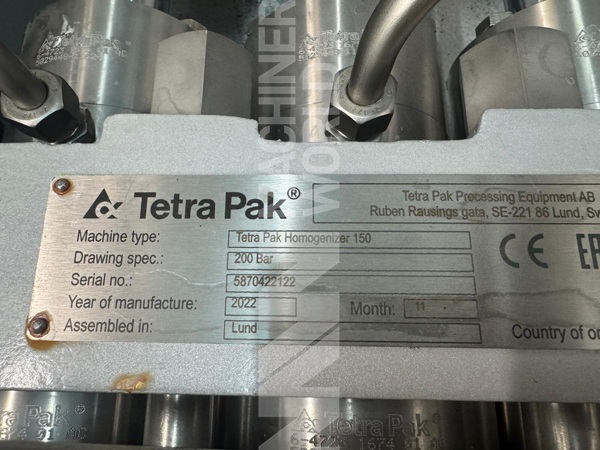

High Pressure Piston Homogeniser

- Make: Tetra Pak, Sweden

- Type: Tetra Pak Homogenizer 150

- Function: High Pressure Piston Homogeniser

- Serial Number: 5870422122

- Year of Manufacture: November 2022

- Maximum Operating Pressure: 200 Bar

- Number of Stages: 2 Stages

- Number of Pistons: 3x Pistons

- Controls: Includes Control Panel

Also includes the following:

- Powder/Dry Ingredient Feed Hopper

- Twin Screw Pump for Finished Product

- Various Tetra Pak ThinkTop Valves

- Tetra Pak Plate Heat Exchanger Pasteuriser

- Tetra Pak Hot Water Set

- Intermediate Jacketed Tank with Top Mixer

- Approx 2,450 L Holding Tank for Product

- Various Pumps

- Interconnecting Pipework

- Control Panel with Frequency Inverter with Touch Screen HMI

Not Included:

- PLC (This Mix Plant was controlled by a centralised Control System, which controlled the entire factory)

Condition:

- NEVER USED

Download Technical Doc

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn