Description

This is a used Tetra Pak Tetra Scanima B200-500VAA Jacketed Vacuum Capable Universal High Shear Mixer. This Tetra Pak Tetra Scanima B200-500VAA Jacketed Vacuum Capable Universal High Shear Mixer has a total internal volume of approx 700 Ltr, with a working volume of Approx 500 Ltr (Net Volume). Tetra Pak Tetra Scanima B200-500VAA Jacketed Vacuum Capable Universal High Shear Mixer comes with Bottom Mounted Variable Speed Turbo High Shear Mixer and top mounted Scraped Surface Mixer. Tetra Pak Tetra Scanima B200-500VAA Jacketed High Shear Mixer comes with an In-built Vacuum Pump and fully Integrated Control Panel with Allen Bradley PLC & Allen Bradley Touch Screen HDMI & Frequency Controlled Inverter.

Tetra Pak Tetra Scanima B200-500VAA Jacketed Vacuum Capable High Shear Mixer comes with patented Dynamic High Shear HS Mixing Head and can run on High Shear Mode & Low Shear Mode, depending on product and mix consistency required. Also Dynamic HS Head design allows CIP Cleaning of behind primary seals.

Tetra Pak Tetra Scanima B200-500VAA Jacketed Vacuum Capable High Shear Mixer are versatile universal Mixer and well suited for creating Emulsions, Pastes, Creams, Processed Cheese, Cream Cheese, Mayonnaise, Plant Based Vegan Cheese, Sauces, Ketchup and are very popular in the food, cosmetic & pharmaceutical, drinks & beverage industries. Tetra Pak Tetra Scanima B200-500VAA Universal High Shear Mixer comes with external recirculating jacket for heating or cooling & Direct Steam Injection for cooking/pasteurisation. Currently held as stock, this Tetra Pak Tetra Scanima B200-500VAA Jacketed Vacuum Capable Universal High Shear Mixer is available for Immediate Sale.

Specification

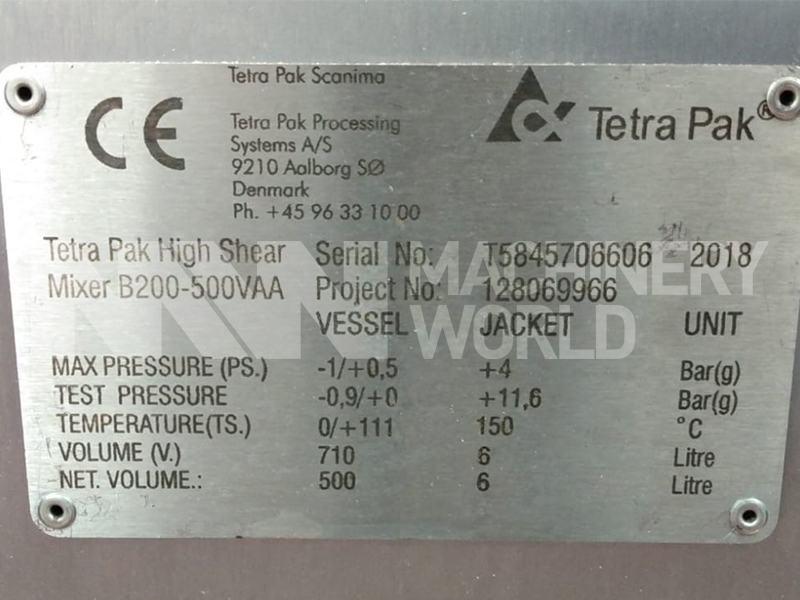

- Make: Tetra Pak Processing

- Type: Tetra Pak High Shear Mixer B200-500VAA

- Model: Tetra Pak Scanima Batch Vacuum Capable Universal High Shear Mixer

- Serial Number: T5845706606

- Year of Manufacture: 2018

- Gross Internal Volume: Approx 710 Litres

- Net. Working Volume: Approx 500 Ltr

- Processing Batch Parameters:

Capacity (Kg per Hour): Approx 3,000 kg per Hour (Varies depending on actual Product & Process)

Capacity (Batches per Hour): Approx 6 Batches per Hour (Varies depending on actual Product & Process) - Jacketed: Yes, External Re-circulation Jacket for Heating (or) Cooling

- Steam Injection: Internal Direct Steam Injection

- Steam Consumption: Approx 500 kg per hour

- Cooling Water Consumption: Approx 5,000 LPH

- Vessel Operating Pressure: -1 (Full Vacuum) to +0.5 Bar

- Jacket Working Pressure: 4 Bar

- Vessel Max Operating Temperature: 111 deg C

- Jacket Max Operating Temperature: 150 deg C

- Installed Power: 52kw, 380-480V, 3-Ph & 50/60Hz

- High Shear & High Speed Mixer:

Model: Dynamic HS Mixing Head with CIP Cleaning Behind Primary Seals

Mixing Modes Available: High Shear Mode & Low Shear Mode

Bottom Mounted High Shear High Speed Turbo Mixer

Speed: Variable Speed (Comes with Danfoss Frequency Controlled Inverter) - Slow Speed Mixer:

Model: Top Mounted Scraped Surface Mixer

Scraped Surface: Internal Side Wall & Bottom Floor of Vessel - Vacuum Pump: Yes, comes with Fully Integrated In-built Vacuum Pump

- Control Panel:

Fully Integrated

PLC Make: Allen Bradley PLC with Recipe Management System/Program

HDMI Make: Allen Bradley Touch Screen HDMI

Speed Control: Danfoss Frequency Controlled Inverter for Speed Control of Bottom High Shear Mixer - Inlet: Bottom Inlets with Pneumatic Controlled Valves

- Outlet: Bottom Outlet with Pneumatic Controlled Valve

- CIP: Top Entry Internal CIP Spray Head

- Manway: Top manway with Secure Rectangular Lid

- Additional Details:Sight Glass with Light

Dimensions

- Length: 3578mm

- Width: 1665mm

Country of Manufacture

Denmark

Download Technical Doc

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn