Description

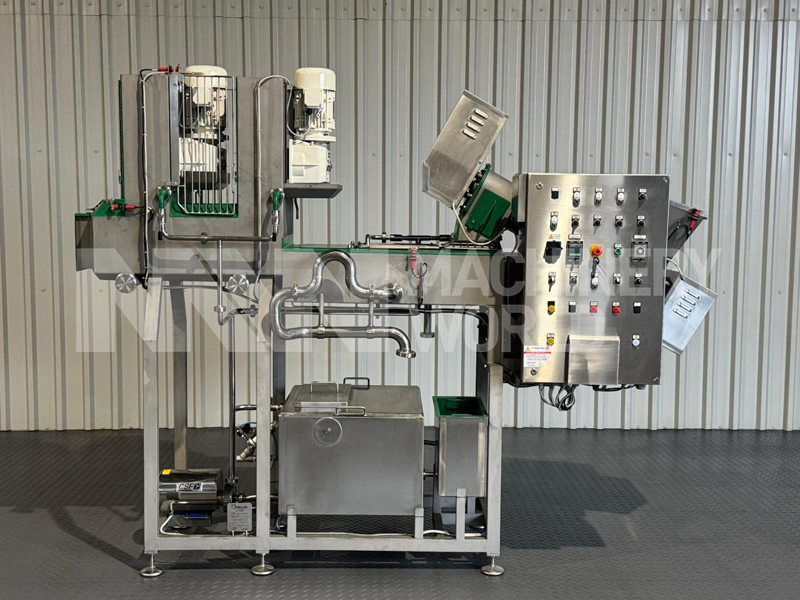

Available for sale is this pre-owned MilkyLab Filatrice Lab 11_50 Mozzarella Cooker-Stretcher, manufactured in 2018 in Italy and NEVER USED in production. The “filatrice” model is specifically designed for the production of pasta-filata cheeses such as mozzarella, buffalo mozzarella, burrata, and similar fresh cheeses.

The machine offers an adjustable production capacity of up to 300–400 kg per hour, depending on product characteristics, moisture content, and molding size, making it ideal for small to medium-scale cheese production or R&D facilities.

Built by MilkyLab, a trusted Italian manufacturer, this unit combines precision, reliability, and efficiency, allowing consistent stretching and shaping of high-quality cheese products.

Working principle

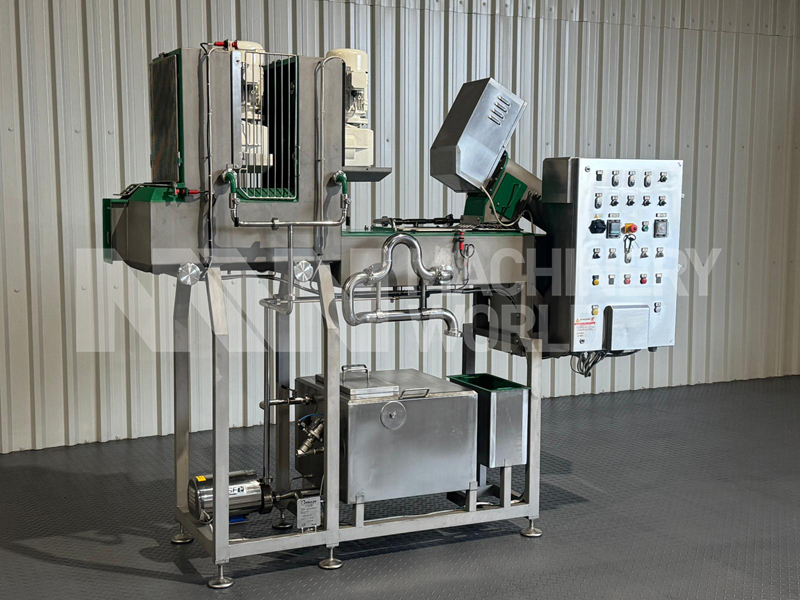

This machine is specifically designed for stretching curd in the production of stretched-curd cheeses. Product feeding and evacuation are performed manually by a dedicated operator, while the entire production cycle is controlled via an intuitive electrical panel, ensuring precise operation and consistent results.

The process begins by introducing curd into the hopper of the loader, positioned above the stretching vat. Once cut, the curd falls into the auger compartment, which is pre-filled with water heated to 75–80°C. In this compartment, the curd undergoes initial cooking and melting, while the two augers push and channel the pasta towards the diving chambers via a bulkhead at the top of the vat.

Within the diving chambers, the pasta is stretched to the desired consistency using two diving paddles and a fork, preparing it for final shaping. At the end of the cycle, a bulkhead at the outlet regulates the controlled release of the product.

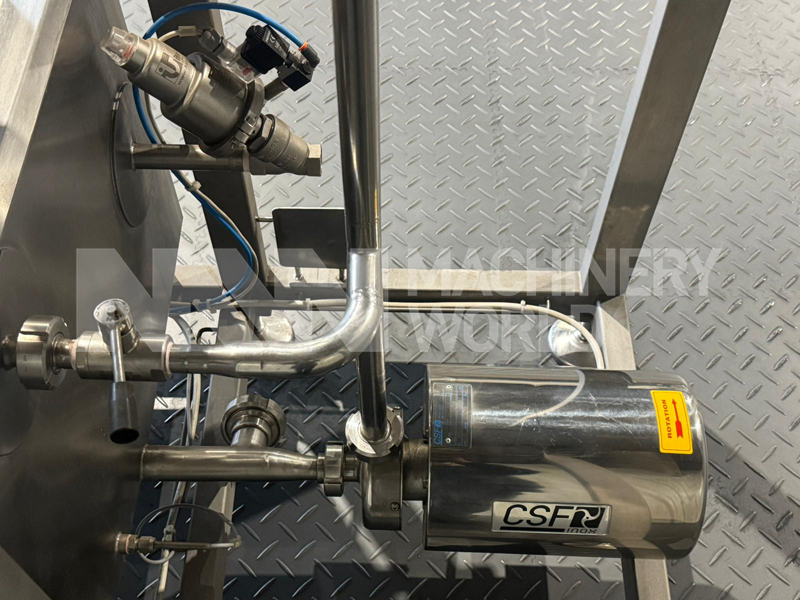

The final stretching is influenced by several factors: residence time in the auger and diving compartments, operating temperature, and the amount of buttermilk drained through a specially designed ball valve. These controls allow operators to achieve consistent texture, elasticity, and quality in every batch.

This machine offers a reliable, efficient, and precise solution for artisanal and industrial cheese production, combining manual handling with automated processing to optimize product quality.

Specification

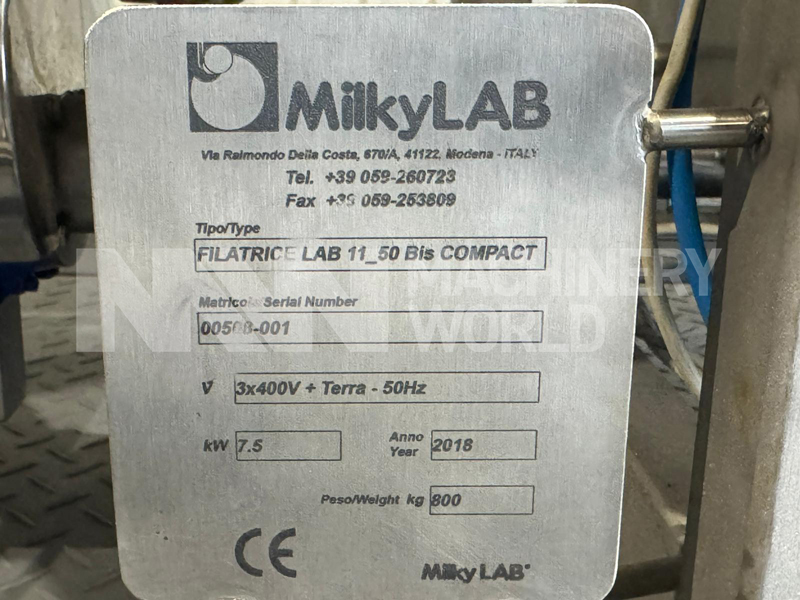

- Make: MilkyLab, Italy

- Model: Filatrice Lab 11_50 Bis Compact

- Function: Mozzarella Cheese Cooker Stretcher Moulder

- Year of Manufacture: 2018 (NEVER USED)

- Capacity: Approx. 300-400kg per hour (Capacity varies depending on the product characteristics, moisture and moulding size)

- Installed Power: 7.5kw

- Electrics: 3ph + 400V & 50HZ

- Construction: Stainless Steel 304

- Operating pressure (Direct Steam): 1.5 Bar (Maximum 2 Bar)

- Air consumption: 1NL/per cycle

- Documentation available (Technical, Electrical & Spare Parts)

Dimensions

- Length: 2995mm

- Width: 1100mm

- Height: 2350mm

- Net Weight: 800 kgs.

Country of Manufacture

Italy

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn