Description

High pressure homogeniser with excellent performance and reliability.

ROKK 4 Series homogenisers / piston pumps are available with capacities from 1000-2000 lt/h as no stage, one stage or double stage depending on application.

The Principle of Homogenisation

The unhomogenised product enters the valve area at high pressure and low velocity. As the product enters the adjustable, close clearance area between the valve and the seat, there is a rapid increase in velocity with a corresponding decrease in pressure. The intense energy release causes turbulence and localised pressure differences, which tear apart the particles. The homogenised product impinges on the impact ring and exits at a pressure sufficient for the next processing stage.

MonoBlock

The MonoBlock (compression head) is manufactured out of a high tensile, corrosion resistant, forged, ultra-high quality stainless steel and checked for imperfections using ultrasound equipment. The compression head for sanitary applications provides an in-line flow pattern and minimises the number of sealed areas. The block features removable top, bottom and front flanges for easy maintenance and has an ultra clean design without dead ends. The semi-spherical valves system allows smooth machine operation, for both low and high viscosity products.

Machine Features

- Designed according to the EU safety rules (CE standards)

- Engineered, manufactured and tested according to ISO EN 9001 Quality System

- Engineered and designed for easy maintenance and cleaning (CIP and SIP)

- Suitable for abrasive and viscous products

- Automatic homogenisation pressure controller with pneumatic adjustment (optional manual)

- Stainless steel construction (Frame) and electrical panel board

- Less footprint with ergonomic design

- Sanitary design analogue diaphragm high pressure gauge

- V belts drive train and gearbox speed reduction unit

- AC motor drive

Specifications

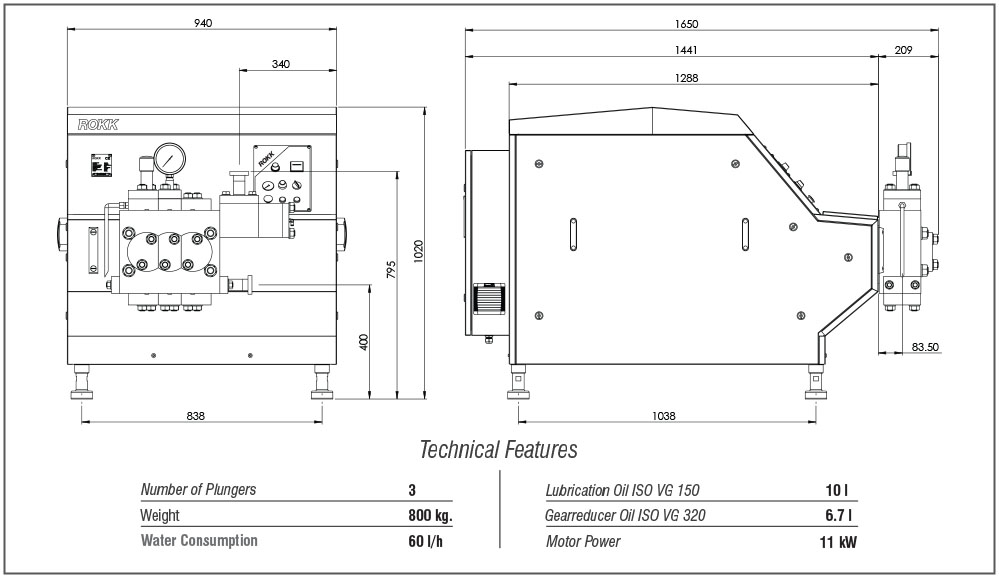

| Dimensions (mm) | 940w x 1650d x 1020h |

| Weight | 800 kg |

| Capacity | From 1000-2000 lt/h |

| Motor Power | 11 kW |

| Water consumption | 60 ltr/hr |

| Number of Plungers | 3 |

Download Technical Doc

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn