Description

These Universal Multi-functional Vacuum capable Process Cutters – Mixers (CCM – Cooker Cooler Mixer) are configurable for many different applications, some examples are processed cheese, dressings, sauces, baby food, confectionery fillings, almond paste, mayonnaise & ketchup and be able to handle different tasks such as mixing, emulsification, homogenisation, cooking – heating via Direct Steam Injection, heating (or) cooling via external double jacket, particle size reduction, cooking under vacuum condition & deaeration using vacuum pump.

Specification

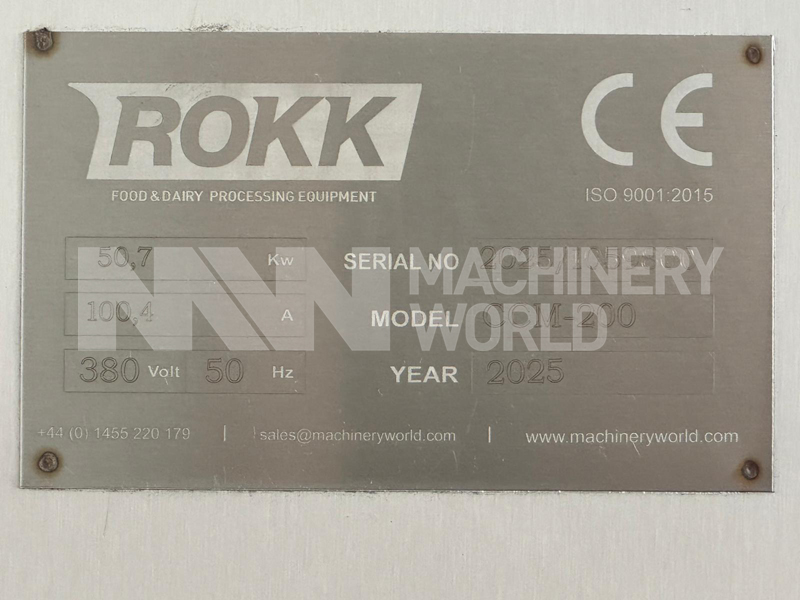

- Brand: ROKK Processing, UK

- Model: CCM200

- Function: Universal mixing cooker

- Approx Bowl Internal Volume: 200 liters

- Year of Manufacture: 2025

- Max Product Working Capacity: Approx 170 liters/ batch

- Batch Processing Time: Approx 8-12 minutes (Varies depending on type of product & process)

- Max Processing Temperature: 95 deg C

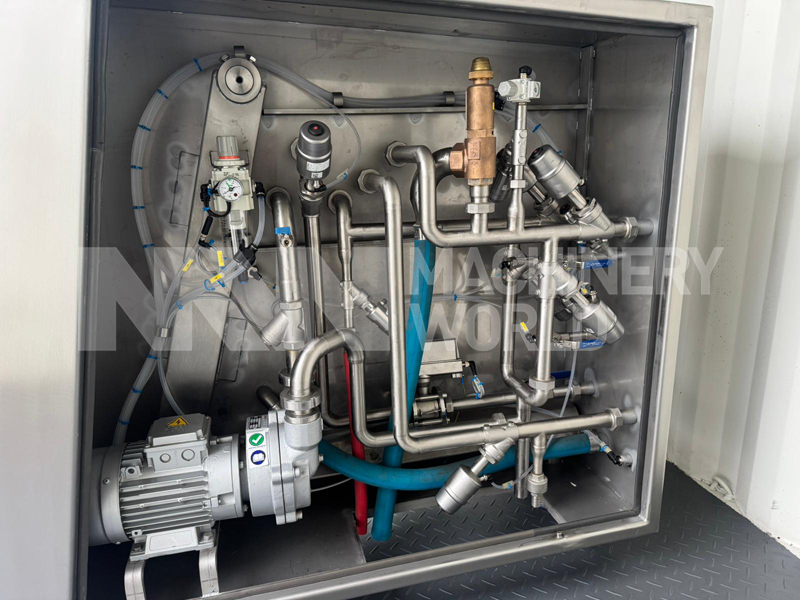

- Hydraulic Tilting Assembly

- Hydraulic Opening & Closing of Lid

- Direct Steam Injection

- External Double Jacket for Heating [or] cooling

- Double Jacket Working Pressure: 2 Bar

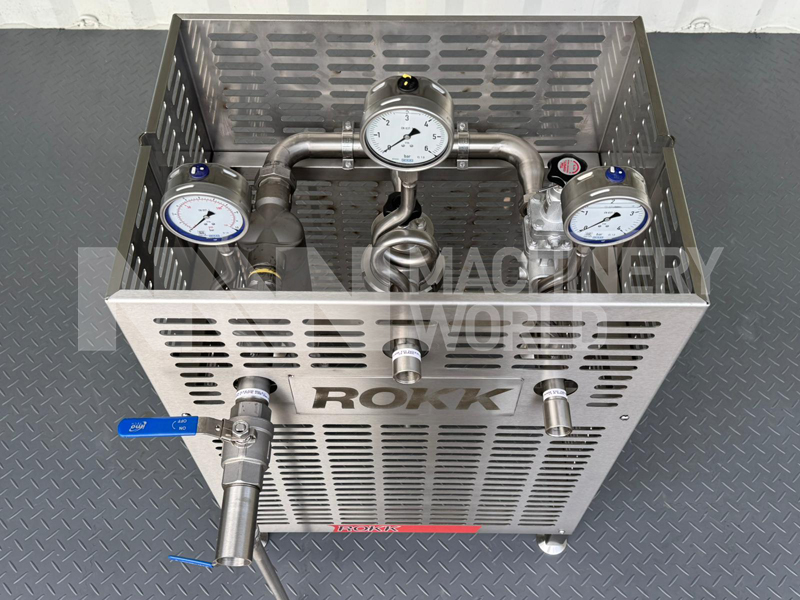

- Vacuum Rated with In-built Vacuum Pump

- Vacuum Pump Motor: 2.2kw, 3-Ph, 380V

- Pneumatic Flushed Discharge Valve

- PLC with Touch Screen HDMI Panel

- Main Bottom Drive Motor: 45kw 3-Ph, 380V

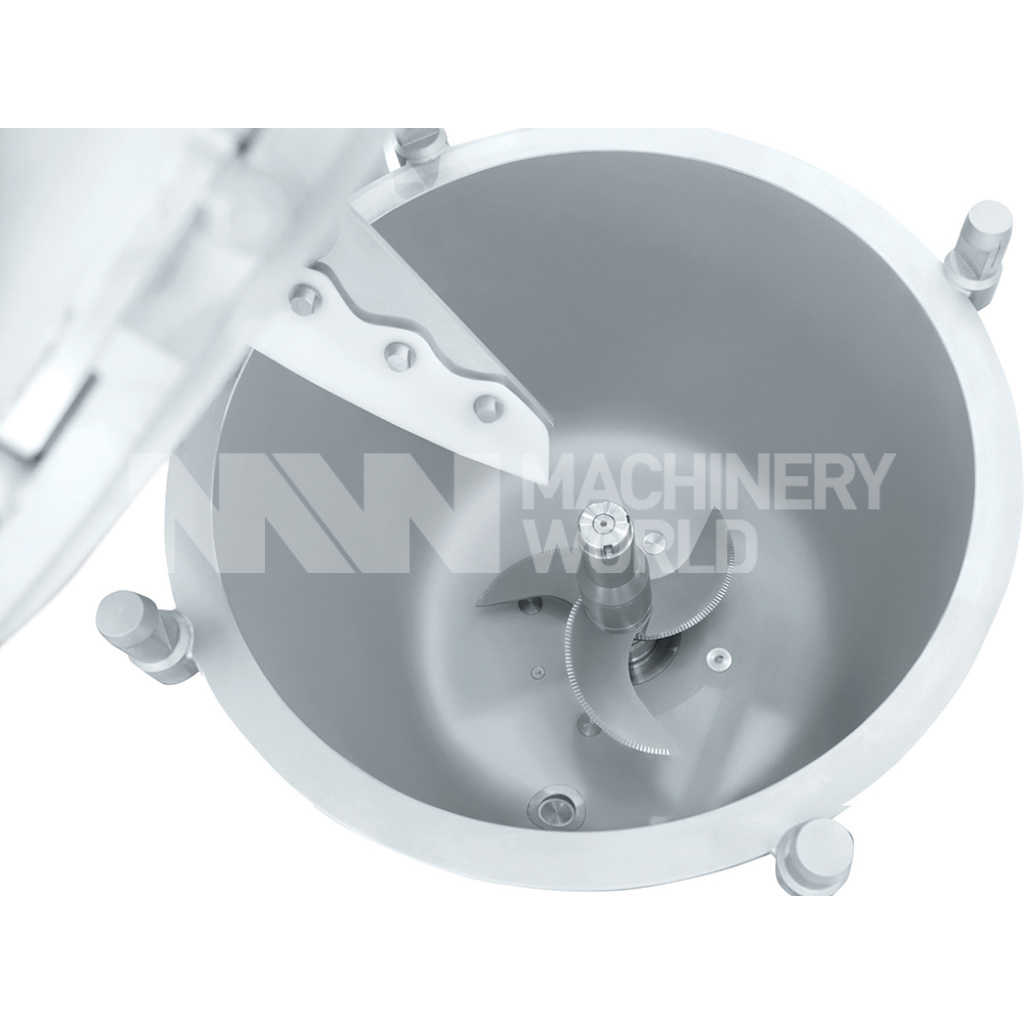

- Bowl Cutter: 3 Knives

- Bottom Cutter Speed: 0 to 3000 RPM (Max)

- Frequency Controlled Inverter for main Motor (Precise Speed Control)

- Side & Top Scrapper: Top Mounted

- Side & Top Scraper Motor: 1.5kw, 3-Ph, 380V

- Direct Steam Injection – Filter Station with Culinary Steam Filters Installed

- See ‘Technical Doc’ link for ROKK Brochure.

Features

- Short Batch Time

- Energy Efficient

- Easy Integration into existing Production Line

- PLC Controlled with Recipe Management

- Configurable for many different product applications

- Complete product emptying capability (Minimal Product Losses)

- Precise Speed Control via Frequency Controlled Inverter

Optional

- Vacuum Condenser for Cooling & De-humidification

- Max Processing Temperature: 125 deg C

- Product Buffer Tank

- Product Discharge Pump

- Flowmeter for Oil or Liquid Ingredient Dosing

- Floor Mounted Hoppers for Dry Ingredient Feed via Vacuum Suction

- Top Mounted Funnel for Ingredient Feed-In

- Inline Mechanical High Shear Homogeniser (MicroCUT)

- Bin Lifter with Bins

Download Technical Doc

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn