Description

Simon Frères MD1219TP Contimab Continuous Butter Churn Plant

High-Capacity Industrial Butter Production System (1,200 – 2,500 kg/hour)

The Simon Frères MD1219TP Contimab Continuous Butter Churn Plant is a robust and fully integrated industrial solution engineered for large-scale, continuous butter production. Manufactured in France by Simon Frères, a long-standing specialist in buttermaking equipment, this plant is designed to meet the rigorous demands of commercial dairy processing facilities, offering exceptional throughput, hygienic design, and seamless integration with downstream processing and storage infrastructure.

Performance & Capacity

Throughput: Capable of producing approximately 1,200 – 2,500 kg of finished butter per hour, depending on cream characteristics and process parameters.

Continuous Operation: Optimised for uninterrupted production, enabling high yield and consistent product quality over extended production runs.

Core Components & Plant Configuration

This comprehensive buttermaking plant includes the following integrated modules:

- MD1219TP Contimab Continuous Butter Churn: Central processing unit where cream is converted into butter through controlled mechanical agitation and thermal management.

- Simon Frères ST500 Butter Silo: Intermediate storage silo designed to hold bulk butter prior to packaging or further processing.

- Simon Frères SRE Butter Reworking Tank: Facilitates reworking, batching, or texturising of butter to achieve target consistency or formulation.

- Pumping & Transfer System: Includes dual Staflow pumps for reliable product transfer and circulation, designed to handle high-viscosity dairy products without compromising texture.

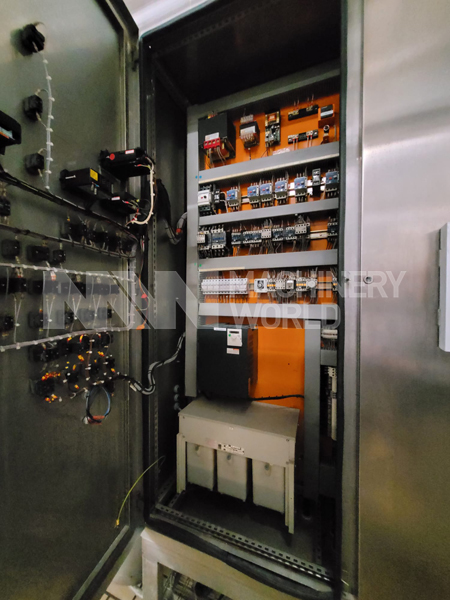

- Power Section & Control Panel: Centralised electrical drive and automation package, providing precise process control, safety interlocks, and ease of operation.

- Interconnecting Pipework & CIP (Clean-In-Place) Accessories: Fully fitted stainless-steel piping with CIP capability to ensure regulatory hygiene standards and reduce cleaning downtime.

Technical & Operational Features

Continuous Buttermaking Technology: The Contimab design is tailored for continuous processing, offering superior control over churning, cooling and buttermilk separation compared with batch churns.

Modular Design: Each major subsystem is modular, enabling flexible layout within production plants and compatibility with upstream cream handling and downstream packaging lines.

Hygienic Food-Grade Construction: Constructed from high-grade stainless steel with sanitary fittings and surfaces to maintain product safety and ease of sanitation.

CIP Integration: Built-in CIP supports rapid, automated cleaning cycles, reducing manual labour and ensuring compliance with food safety standards.

Application & Industry Use

This butter plant is ideal for commercial butter production operations, including dairy cooperatives, food manufacturers, and large-scale foodservice suppliers. Its versatility supports production of a wide range of butter types—salted, unsalted, cultured or sweet—by adjusting process and formulation parameters.

Proven Reliability & Provenance

Simon Frères has a long history of manufacturing butter processing machinery, with continuous churn technologies trusted in dairy installations across Europe and beyond. The MD1219TP model reflects decades of refinement in continuous buttermaking design and industrial automation

Country of Manufacture

France

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn