Description

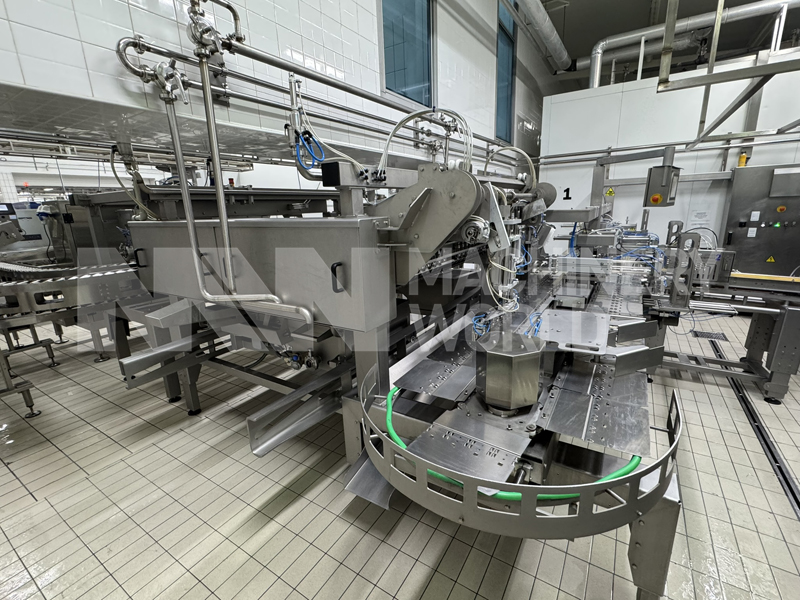

A complete, high-performance Vojta Arctic CX 800/8 ice cream extrusion line (Year 2016) currently in full production and available after August 2026, when it will be replaced by a larger-capacity system.

The line is well-maintained, fully equipped, and presently producing Magnum, Mini-Magnum, Funny Face, and Sandwich products, with output capacities of up to 15,000 pcs/hour.

Included with the line are 2 × MCM W800DX flow wrappers (Installed new in 2022), a Bitzer refrigeration system, and a spiral cooling tunnel.

A video link showcasing the plant installed and running on multiple product formats is available below.

Key details

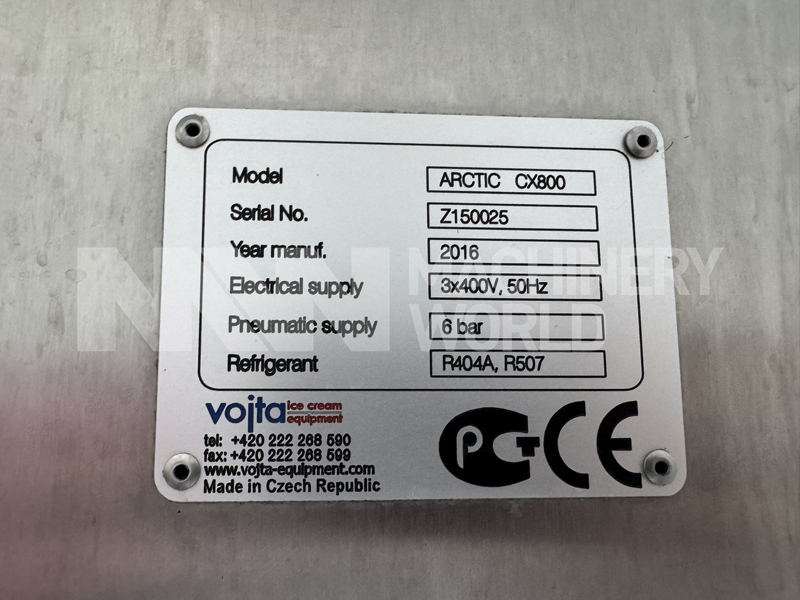

- Manufacturer: Vojta

- Model: Arctic CX 800/8

- Function: Ice cream stick extrusion line

- Year of manufacture: 2016

- Serial number: Z150025

- Currently producing: Magnum, Mini-Magnum, Funny Face, Sandwich

- Capacity (Stick products): 15,000 pcs / hour (20 min HT)

- Capacity (Sandwich): 7000 pcs / hour (24 min HT)

- Number of trays in the tunnel: 710 pcs

- Tray dimensions: 302 x 320mm

- Product freezing time: 15-65 minutes

- Maximum product height: 150mm, placed in hole of tray or, 110mm placed onto tray surface

- Electrical requirements: 400V, 3ph, 50hz

- Pneumatic supply: 6 bar

- Includes 2x MCM W800DX automatic wrapping machine (Replaced for new in 2022)

- Includes standalone Bitzer refrigeration system and spiral cooling tunnel

- Includes technical documentation, electrical drawings and spare parts catalogue

- Cooling Tunnel dimensions: 8500 x 4150 x 3180mm (LxWxH)

- Overall dimensions: 14.7 x 11.4 x 3m (LxWxH)

Basic machine

- Isothermal box with sandwich panels of high density injected polyurethane, thickness 125mm. Sandwich panels with finishing Znl/Znl, galvanized sheet steel.

- Inspection door with safety handle inside, internal electrical light fittings, safety switch

- Standard prefabricated floor with water resistant fiberglass

- Inside floor is covered stainless steel AISI 304, thickness 3mm with anti-slip top cover

- Inner mechanical robust structure, built completely in stainless steel.

- Central pneumatic tension station for the automatic compensation of chain’s dilatation. Precise tension adjustment for long chain life. Automatic tension disconnection when machine out of use

- EasyTens system for precise and equal chain extension during chain life

- Water tight ball bearings, enclosed in support suitable for very low temperatures

- Stainless steel lubrication-free chain (chain pitch 76,2mm), carrying the trays. Lubrication free chain ensures the highest hygiene standard for production. The chain is driven by motor-reducer assembly placed inside the tunnel. Electronic control and synchronisation via frequency converter.

- Adjustable safety breaks and overload control to stop the chain whenever the stress limit is exceeded

- Refrigeration system with freon evaporator with 8 high speed fans for the air circulation, all mounted inside the box

- Hot gas defrosting system

External worktable

The worktable prepared for mounting of working station. All exterior surfaces and components from stainless steel or stainless materials. Open design for easy sanitation and maintenance.

- Main electrical control panel built according to the international safety regulations

- PLC control unit for synchronization of all parts of the line

- Preset values for 10 products (40 products possible). Alarm and error messages for easy diagnostics, backed by help screens

- Main operator panel is 12″ UNI OP color graphic touch screen. Screens and labels in English

- Secondary functions activated by compressed air or frequency controlled motors and synchronised with the main drive by means of PLC control

- Cleaning and drying devices for trays. Consists of following operations:

- Pre-spraying with clean water

- Rotating brush cleaning. Detergent hopper above brush

- Tray surface rinsing with clean water

- 2x Compressed air drying stations

- Hammer mechanism to detach hardened products from tray surface (upper position)

- Product remover arm – for products not picked up by pincers

- Set of 710 flat stainless steel trays (302 x 320mm)

Assembly for vertically extruded products:

- Device to extrude, cut and deposit the products on trays in preset number and position, consisting of:

- Vertical extrusion system servo driven and working in synchronisation with cutting unit and tray chain

- Horizontal cutting system with double heated wire, adjustable wire temperature

- Cutting 8 products per tray in 2 rows (2×4), product pitch 76,2mm

- Single stick inserter, pneumatically operated, with magazine to introduce the wooden stick, one by one, into the ice cream slice while being extruded

- Stick magazine interchangeable, for following dimensions:

- – 94 x 16 x 2mm

- – 94 x 10 x 2mm

Flow Wrappers (2 pcs)

- Manufacturer: M.C.M S.R.L, Italy

- Model: W800DX

- Serial number: 22/062 & 22/063

- Year of construction: 2022

- Total Weight: 2,300 kgs

- Electrical supply: 400V, 50Hz, 3Phase

- Total installed power: 12 kW

- Air supply: 6 bar @ 600 Nl/hr

- Exclusions: Videojet Inkjet Printers (as seen on pictures)

Cooling Tunnel

- Cooling Tunnel dimensions: 8500 x 4150 x 3180mm (LxWxH)

- No. of Tiers: 8

- Tiers space: 160mm

- No. of cooled trays: 690

- Product/tray – Stick: 8pcs/Tray

- Chain pitch: 76,2mm

Refrigeration System

- Water cooled compressor/condensor assembly to supply the liquid refrigerant

- Painted steel frame to support all components, the control and the electrical refrigeration plant

- R404A Bitzer Compressor (Screw type) complete with oil, low pressure and high pressure controls and safety devices

- Shell and tune condensor provided with solenoid valve on the water connections

- Electrical control panel

- Piping and cabling up to 10 mts

- Type of compressors: 2 HSN-7471-70

- Refrigeration gas: R404A / R507

- Expansion temperature: -43degC

- Cooling power (-43degC/+30degC): 100 kW

- Cooling water temperature: +30degC max

- Electrical supply: 3x 400V, 50HZ

Country of Manufacture

Czech Republic

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn