Description

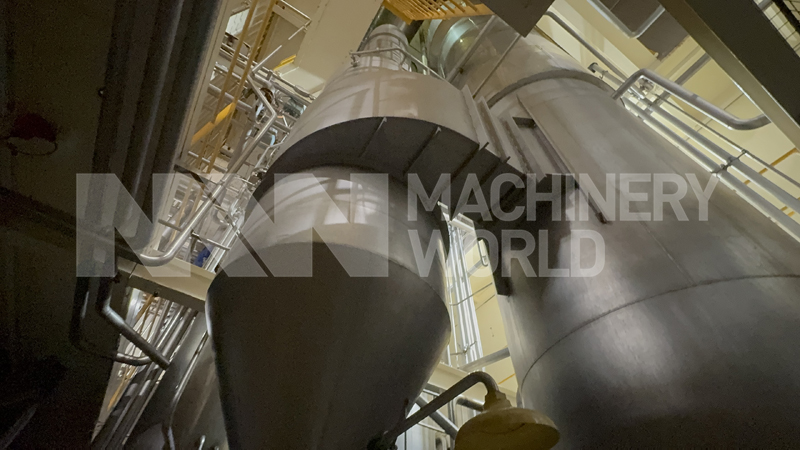

This is a used Stork 4-effect MVR Evaporator Concentrator \plant is a specialized system designed for the concentration of skim milk, typically used in dairy processing industries. The Stork 4-effect MVR (Mechanical Vapor Recompression) Evaporator Concentrator is an energy-efficient system that uses multiple evaporator stages (effects) and mechanical vapor recompression to concentrate skim milk by removing water (as vapor), increasing its total solids content.

Currently installed, this Stork 4-Effect MVR Evaporator Concentrator Plant is available for immediate sale. Note: Download brochure available on ‘Technical Doc’ link and specification shown below, are for information purpose only, as mentioned on manufacturer’s brochure, and the actual machine’s capabilities and efficiencies might vary.

Evaporator Concentrator Features

- Manufacturer: Stork, The Netherlands

- Function: Multi Stage MVR Evaporator Concentrator Plant

- Type of installation: Falling Film Evaporator Concentrator: 4x Effect MVR

- Pasteurisation Temperature: Low Heatr @ 74 deg C & High Heat @ 90 deg C

- Application: Whole Milk, Skim Milk Whey etc

- Vapour Compression: Mechanical Vapour Recompression + Thermal Vapour Recompression

- Vacuum System: Liquid Ring + Vacuum Pumps

Evaporator Specification

- Skim Milk

- Feed In Rate: 29,084 kg per hour

- Solids in Feed: 8.8%

- Water Evaporation Rate: 23,965 kg per hour

- Concentrate Feed Out Rate: 5,119 kg per hour

- Solids in Concentrate: 50% Total Solids

- Temperature of Concentrate on discharge: 65 deg C

- Product Boiling Temperatures:

- Boiling Temeprature Effect 1: 72 deg C

- Boiling Temeprature Effect 2: 69.5 deg C

- Boiling Temeprature Effect 3: 64.3 deg C

- Boiling Temeprature Effect 4: 65.1 deg C

- Consumption

- Steam for Pre Heating: 515 kg per hour

- Water for Seals: 2250 kg per hour

- Cooling Water for Evaporator: 12,000 kg per hour

- Cooling Water for Compressor: 4,500 kg per hour

-

- Installed Electrical Power:

- Feed Pumps: 1x 7.5kw & 1x 11kw

- Concentrate Pump: 5x 4kw, 1x 5.5kw

- Condensate Water Pump: 1x 0.75kw & 1x 5.5kw

- Vacuum Pump: 2x 11kw

- Compressor: 350kw

- Oil Pump of Compressor: 2.2kw

- Guidevane Motor

- Installed Electrical Power:

- Additional Details: Plant Includes CIP Tanks, Tubular Heat Exchanger for Pre Heating

- Detailed pictures & video available of the full line upon request

- Please refer to ‘Technical Doc’ link for detailed spec of Evaporator?Concentrator

Country of Manufacture

The Netherlands

Download Technical Doc

Twitter

Twitter Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn