Description

This is a used Tetra Pak Tetra Therm Aseptic ESL Pasteuriser Plant with Tetra Pak Homogeniser. This Tetra Pak Tetra Therm Aseptic Pasteuriser Plant with Homogeniser has a capacity range on 6,000 LPH to 12,000 LPH and can be used on Milk, Cream, Juice, Oat Milk etc.

This complete ESL (Extended Shelf Life) plant includes a Tetra Pak Homogeniser, ensuring superior product consistency, stable emulsions, and optimal particle size reduction—ideal for UHT milk, cream (up to 40%), and other liquid dairy products, suitable for continuous ESL pasteurisation, and homogenisation applications. Designed for continuous, hygienic, and energy-efficient production, the system features advanced heat treatment, homogenisation, holding tube options, and aseptic operation, meeting global food safety standards. With Tetra Pak’s proven engineering, this ESL line guarantees stable performance, low operating costs, and long-term durability. Perfect for dairy producers looking to scale up to mid- or high-capacity ESL processing, this Tetra Pak ESL plant offers premium product quality, operational efficiency, and the trusted performance of Tetra Pak technology. Currently held as stock, this Tetra Pak Tetra Therm Aseptic ESL Process Plant with Tetra Pak Homogeniser is available for immediate sale. Please note: the attached Technical Doc is provided for reference only; the specifications of the actual equipment offered may vary.

Specification

- Manufacturer: Tetra Pak Dairy & Beverage Systems, Sweden

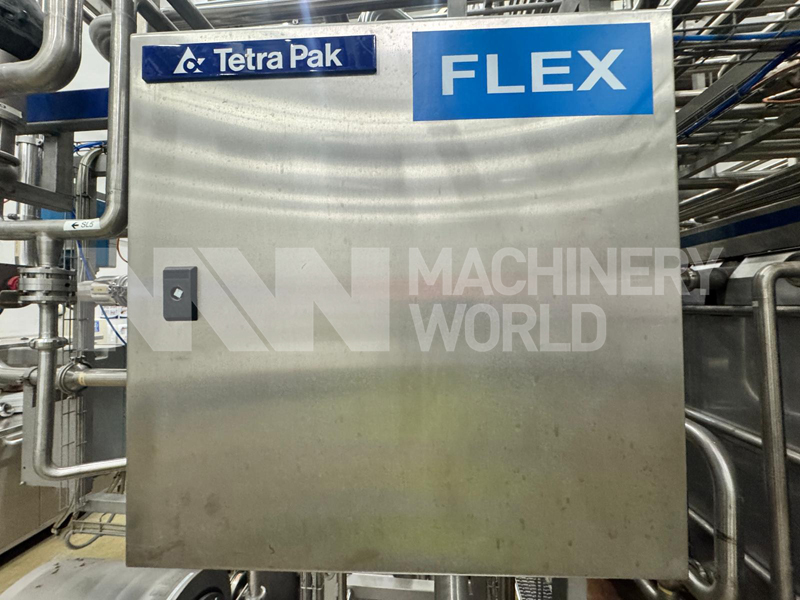

- Machine Type: Tetra Therm Aseptic Flex

- Machine Number: T5844151091

- Function: ESL (Extended Shelf Life) Pasteuriser Plant with Plate Heat Exchanger

- Year of Manufacture: 2010

- Approx Capacity – Flow Rate:

- 13% Whole Milk: 12,240 LPH (Maximum)

- 13% Whole Milk: 6,120 LPH (Minimum)

- 40% Cream: 9,000 LPH

- Design Temperature: 128 deg C

- Recommended CIP Flowrate (Cleaning): Min 24,000 LPH

- Steam Consumption: Approx 250kg per hour

- Ice Water: Approx 43,000 LPH

- Installed Power: Approx 122kw, 3-ph (Including Homogeniser)

- Includes: Tetra Pak High Pressure Homogeniser, various Pump, Valves, Balance Tank, Flowmeter, Tetra Pak C10 KHS Plate Heat Exchanger (Pasteuriser Plate Pack), Holding Tubes etc.

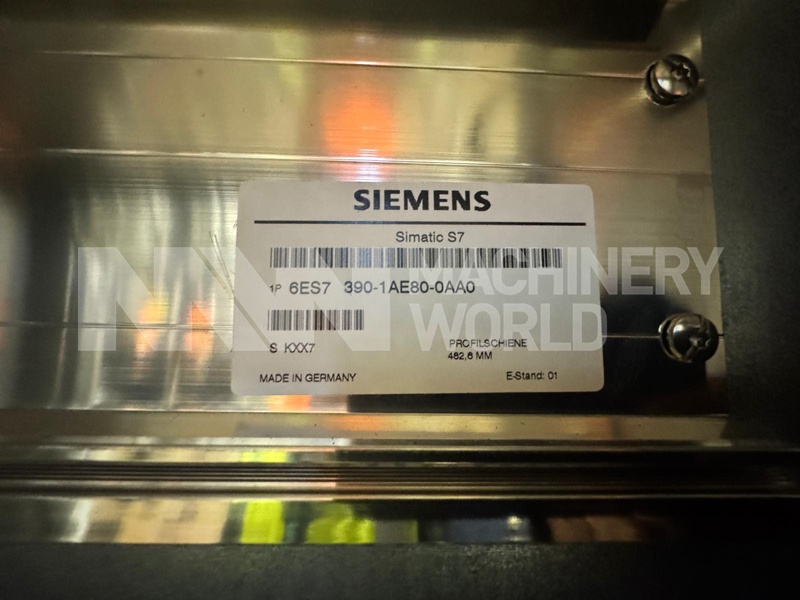

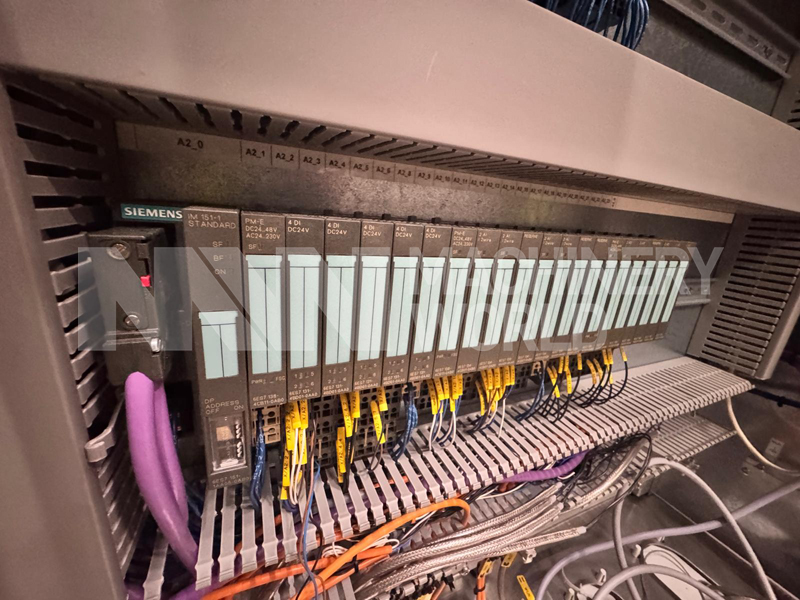

- Controls: Fully Integrated Control Panel with Siemens S7 PLC with Beijer X2 Pro Touch Screen HMI.

Country of Manufacture

Sweden

Download Technical Doc

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn