Description

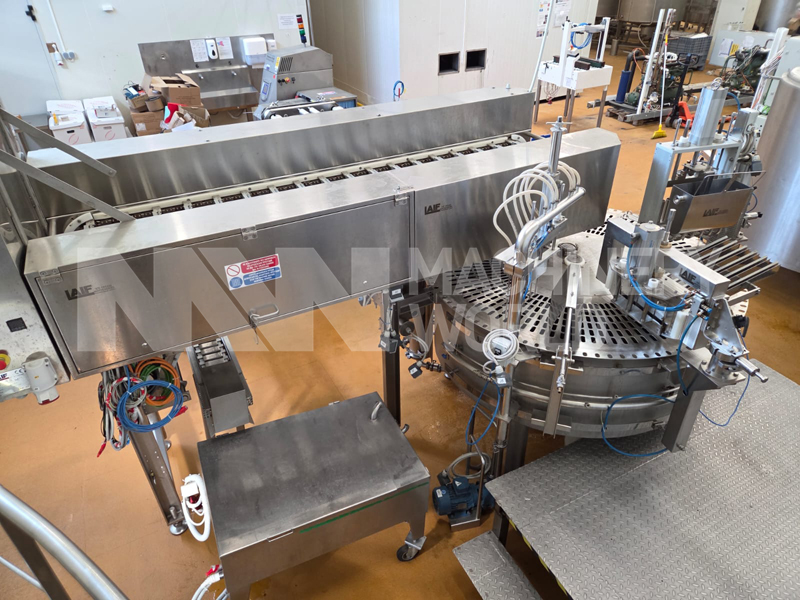

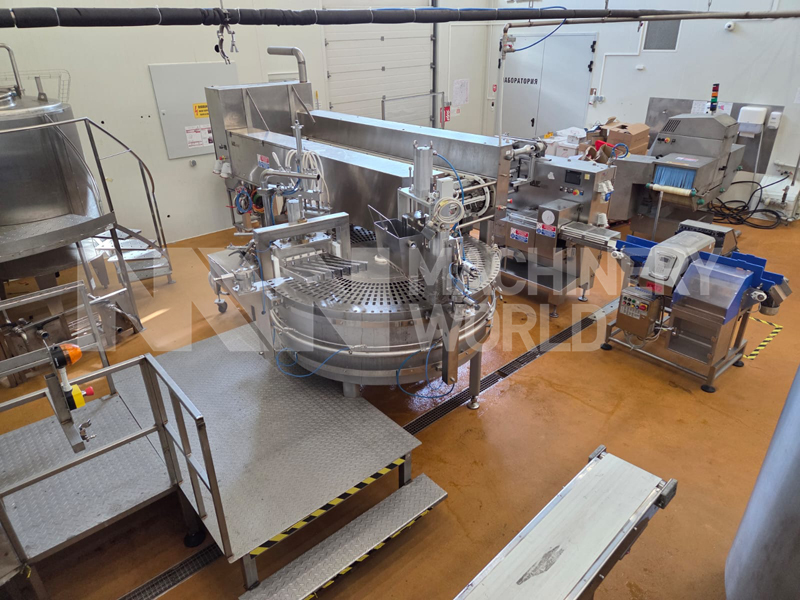

This is a pre-owned GSL 3 Model Rotary 6-Wide Ice Lolly Moulding Machine, manufactured in 2019 by Laief in Italy. With a capacity of up to 6,000 pieces per hour, this compact and versatile line is ideal for small to medium producers of water or dairy-based ice cream products. The machine is equipped with 75ml Lolly Moulds, other moulds are available upon request from the manufacturer.

Main production stages involve:

- The ice cream mix is passed through a freezer to semi-freeze it at a temperature of about -2, – 3°C, depending on the characteristics of the mix; at a positive temperature 2°/3° C in case of water ice mix: the resulting mix feeds the filler hopper. (The type of filling station depends on the product to be filled.)

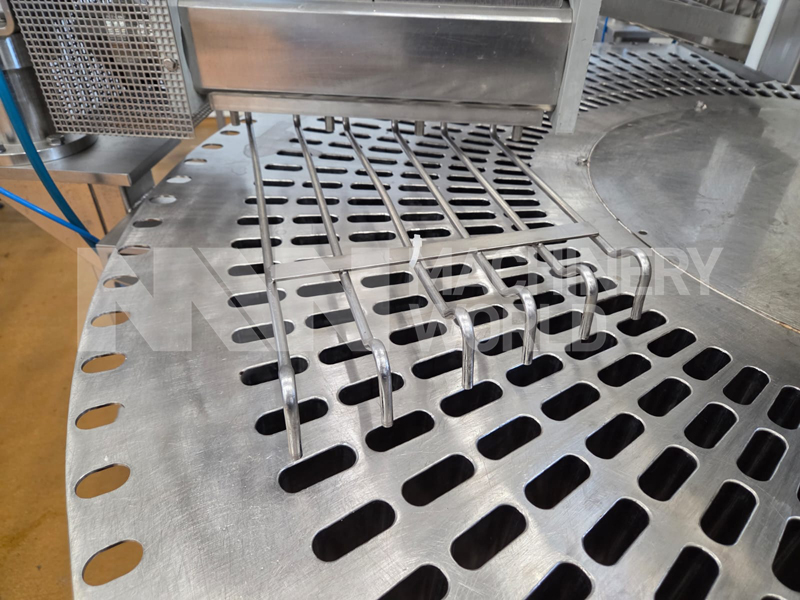

- The calcium chloride brine cooling system starts to freeze the product in the mould. In the simplest version with a single-filler process, the product is allowed to freeze to the point where the ice cream stick can be inserted.

- With the stick inserted, the freezing process can end. The mould with the frozen product arrives above the defrosting station at this point. The defrosting station operates on thermostatically controlled hot water.

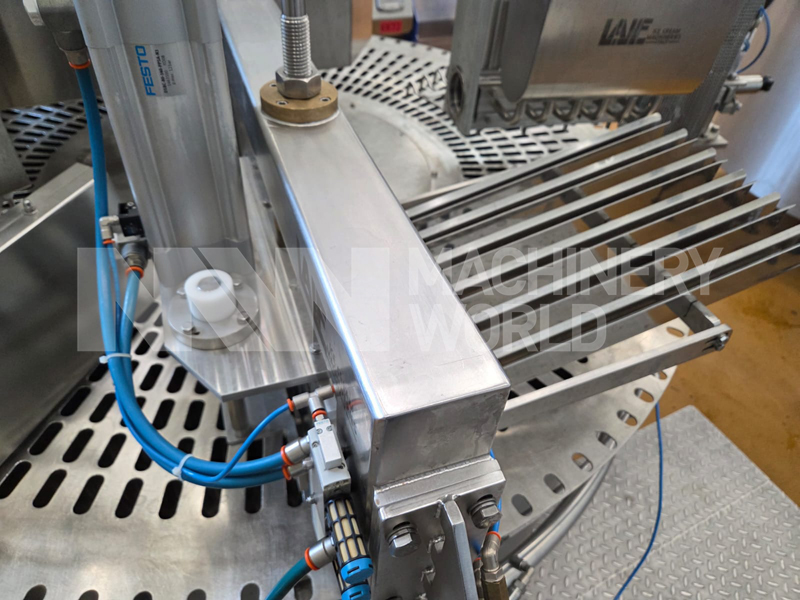

- The prepared pump sprays water under the mould, causing the product to defrost from the mould.

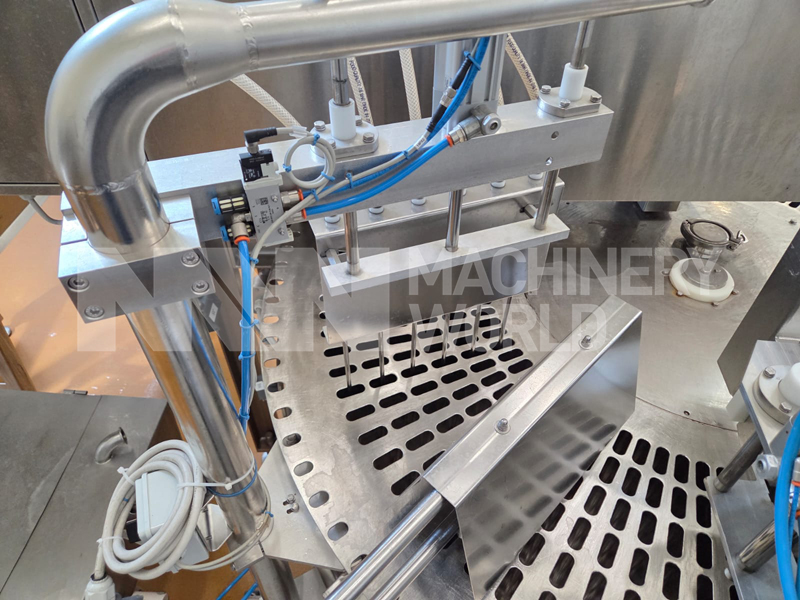

- At this point the extraction line bar descends to the mould, pick up the product from the stick and removes it from the mould. The product is then conveyed to the chocolate coating station to be coated or uncoated.

- Then the product is held suspended on the extraction line for about 40 seconds to give the chocolate time to dry.

- With this stage of production completed, the ice cream is ready to be placed in the wrapping line for final packaging.

Pros of Rotary Machine:

- Reduced water consumption: water is used only for final washing

- Reduced brine consumption

- Reduced product mix water

- Compact layout for easier accessibiltiy

- Cooling time of the chocolate before the packaging stage

Features

- Manufacturer: Laief

- Model: GSL 3 – 6 Wide

- Function: Rotary Lolly Popsicle Moulding Machine

- Year of manufacture: 2019

- Serial number: PP-07-2018

- Capacity: 6,000 pcs / hour

- Moulds included: 75ml (Drawing available on file)

- Construction entirely made of AISI 316 Stainless Steel

- Volumetric Filler (between 0-135ml possible)

- Mould level height: 1241mm

- Brine Pump – Lowara (model ESHS 50-160/55/P25)

- Defrost Pump – Lowara (model CEA 120/5)

- Hot water defrosting tank

- Pneumatic movement of the moulds

- Mould washing system with Hot Water

- 4x descend extration type racks with motion cylinder, ratchet traction chain servo-powdered (10 bars free between chocolate and release). Treated steel chain.

- Festo pneumatics

- Siemens electrical system

- Electrics: 3phase – 380V – 50HZ

- Country of manufacture: Italy

- Full set of documentation included

- Refer to ‘Technical Doc’ link for Layout Drawing of the plant

Includes

- 2x Lolly Mix Storage Tanks

- Chocolate tank

- GWR 6 Flow wrapper

- CEIA THS metal detector

- Hitachi RX ink jet printer

- Refrigeration unit with equipped with 2 Bitzer HSN 7461-70 Compressors (R448A)

Download Technical Doc

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn