Description

This is a used Limitech BMK747 Universal Batch High Shear Mixer DDM Kolding Continuous Pasteuriser Plant. DDM Kolding Continuous Pasteuriser Plant has a gross internal volume of 747 Ltr and working volume of approx 500 Ltr and comes with Top Entry Full Sweep Mixer and Bottom High Shear Turbo Mixer Emulsifier. Limitech BMKL747 Universal Batch High Shear Turbo Mixer is well suited for industrial batch high shear mixer for easy processing and would be suited for either simple mixing or for high shear emulsification & mixing. DDM Kolding Continuous Electrically Heated Pasteuriser Plant is completely skid mounted with a working capacity of approx 300 LPH, depending on the type of product.The product get heated to about 75 deg C which is the Pasteurisation Temperature and includes a set of Holding Tubes for 15 sec Holding Time. DDM Kolding Continuous Electrically Heated Pasteuriser Plant includes SPX Plate Heat Exchanger, Balance Tank, Inoxpa Positive Lobe Pump, Inoxpa Centrifugal Pump and various Valves. DDM Kolding Continuous Pasteuriser Plant is heated by an electrically heated Hot Water Generator.

This complete DDM Kolding Pasteuriser Plant along with a Limitech High Shear Batch Blending System were installed at a major European food & dairy processing facility and available for immediate sale.

Specification

500 Ltr Limitech Batch High Shear Mixer

- Make: Limitech

- Type: BMK 747

- Serial No: 1776

- Year of Manufacture: 2008

- Construction: Stainless Steel

- Model:Batch High Shear Turbo Mixer

- Heating: Product Re-circulation via plate Heat Exchanger

- Single Skin Construction

- Vessel Max Working temp: 100 deg C

- Total Internal Volume of Vessel: 747 Ltr

- Working Internal Volume of Vessel: 500 Ltr

- Top Mixer: Full Sweep Mixer

- Bottom Mixer: High Shear Turbo Mixer

- Lid: Top Hinged Lid Assembly with Safety Grill Mesh

- Control Panel: Remote Control Panel

- Inclusions: Inoxpa Product Re-circulation & Delivery Pump, SPX Plate Heat Exchanger, Process Data PD340 Flow-meter and Hot Water Booster Pump.

- Heating Method: Electrically heated Hot Water Generator, which is recirculated via Plate Heat Exchanger to heat up mixed product.

300 LPH DDM Kolding Continuous Electrically Heated Pasteuriser Plant

- Make: DDM Kolding

- Model: Skid Mounted Pasteuriser Plant

- Type: Continuous Electrically Heated Pasteuriser Plant

- Year of Manufacture: 2014

- Capacity: Approx 300 LPH

- Pasteurisation Temperature: 75 deg C

- Holding Time: 15 Seconds

- Heating Method: Electrically Heated (Built-In Hot Water Generator)

- Includes: SPX Plate Heat Exchanger (Pasteuriser) Inoxpa Positive Lobe Pump, Inoxpa Centrifugal Pump, Holding Tubes, Balance Tank, Inoxpa Valves, Flowmeter & Interconnecting Pipework.

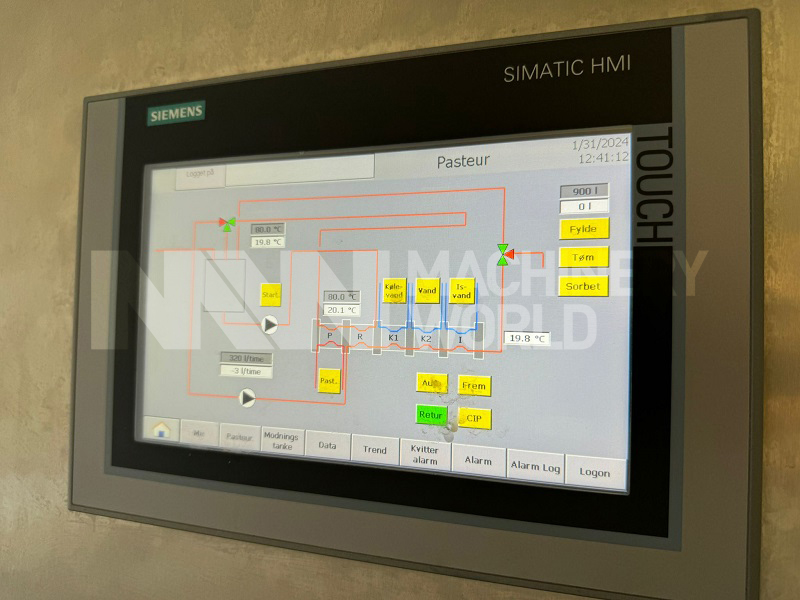

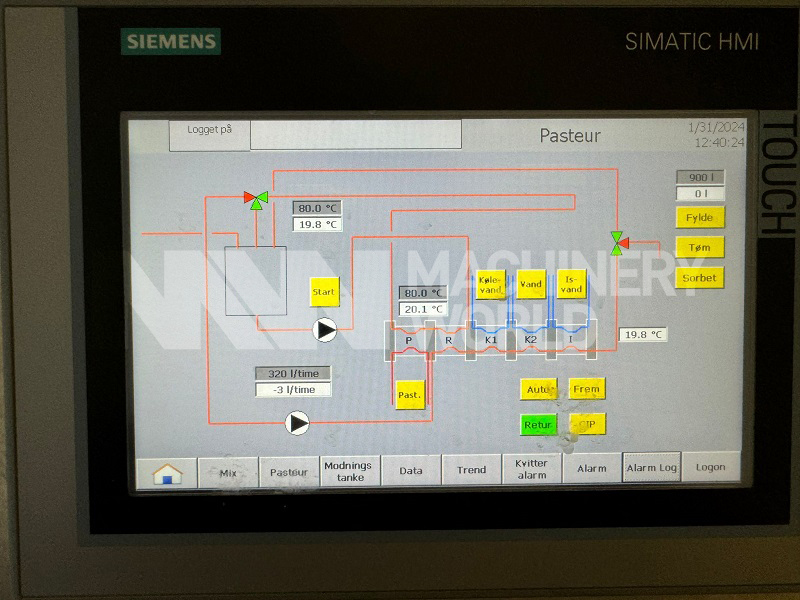

- Controls: Fully Integrated Control Panel with Siemens S7 PLC with Siemens Simatic Touchscreen HMI & Frequency Controlled Inverter for Pumps

- Additional Details: Completely Skid Mounted. Includes Manuals & Drawings.

Country of Manufacture

Denmark

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn