Description

This is an used Tetra Pak Pilot UHT with a capacity ranging between approx 55 LPH to 270 LPH depending on the type of product and UHT Treatment. This Tetra Pak Pilot UHT utilises Indirect UHT & Direct UHT (VTIS). Also included with the Tetra Pak Pilot UHT is an APV Gaulin Homogeniser with 2-stages. This Tetra Pak Pilot UHT was used on the following products: 1) Milk at 140 °C, 2) Condense Milk at 139 °C & 3) Custard Products at 137 °C. However, being a Pilot UHT Plant, this can be used on various other food products which are light including thick & viscous products.

Specification

UHT Heat Treatment Methods

- Indirect Heating in Plate Heat Exchanger

- Indirect Heating in Tubular Heat Exchanger

- Indirect Heating/Cooling in combination of Plate and Tubular Heat Exchanger

- Direct Heating (VTIS) with Steam Injection in combination of preheating in Plate and Tubular Heat Exchanger

- Direct Heating with Steam Infusion in combination of preheating in Plate and Tubular Heat Exchanger

- Direct Flash Cooling with (or) without Vacuum

- De aeration with Vacuum (without Flash Cooling)

Capacity

- Approx ± 55 LPH to 270 LPH – Direct Heating (depending on the type of product)

- Approx ± 55 LPH to 240 LPH – Indirect Heating (depending on the type of product)

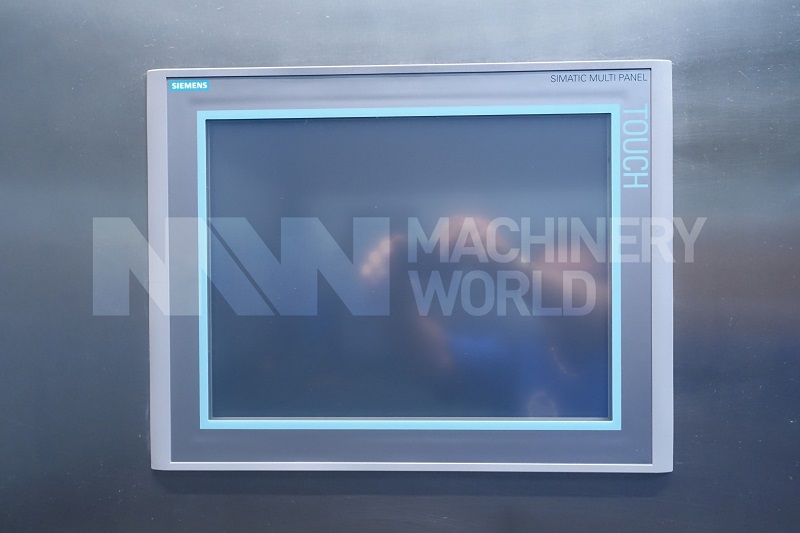

Control Panel

- Fully Integrated on Skid with Siemens PLC and Siemens SIMATIC Touch Screen HMI & Danfoss Inverters for Speed Control of Pumps

Additional Details

- Includes Alfa Laval M3FG Plate Heat Exchanger, Tetra Spiroflo Tubular Heat Exchanger, Balance Tank with Mixer mounted on Skid, Grundfos CRN3 Pumps, Afa Laval Brazed Plate Heat Exchangers, Samson Popsitioner Valve, Various Pneumatic Actuated Valves, ABB Flowmeters, Fristam Pump, Interconnecting Pipework etc

Homogeniser

- Make: APV Rannie

- Type: Pilot Homogeniser

- Number of Stages: 2 Stage

- Number of Pistons: 3

- Control Panel: Fully Integrated with Frequency Controlled Inverter for Speed Control

Country of Manufacture

Sweden

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn