Description

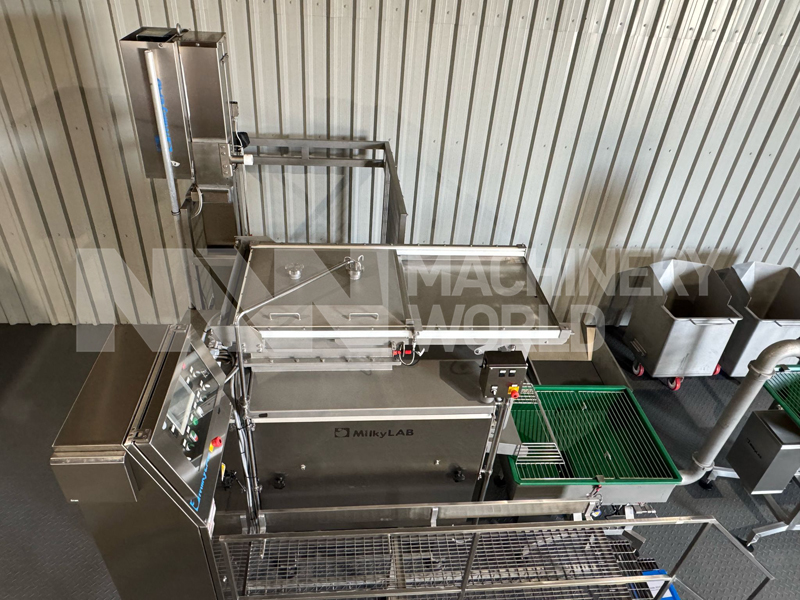

We are offering a used MilkyLAB production line designed for the production of Pasta Filata (Mozzarella, Buffalo Mozzarella, Pizza Cheese), Analogue Mozzarella, and Cheese Spreads. This line includes the following equipment:

-

MilkyLAB 18 Cooker Stretcher

-

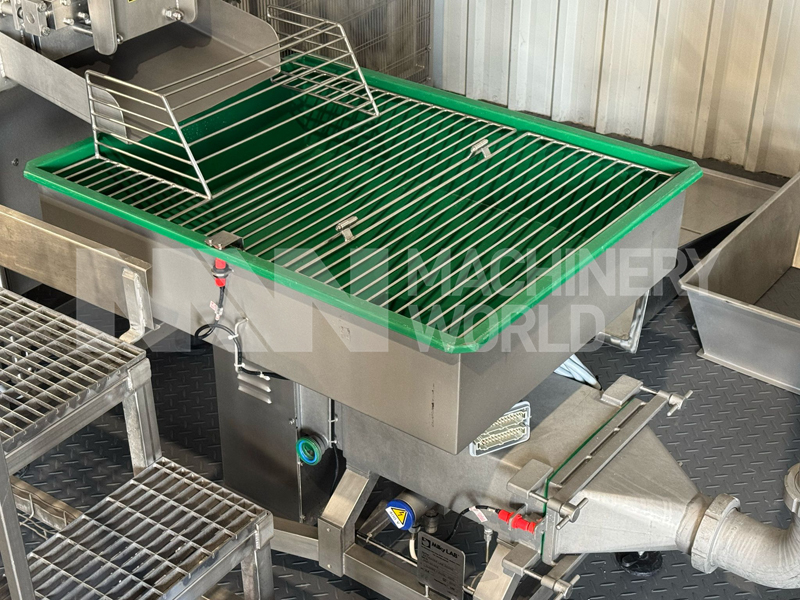

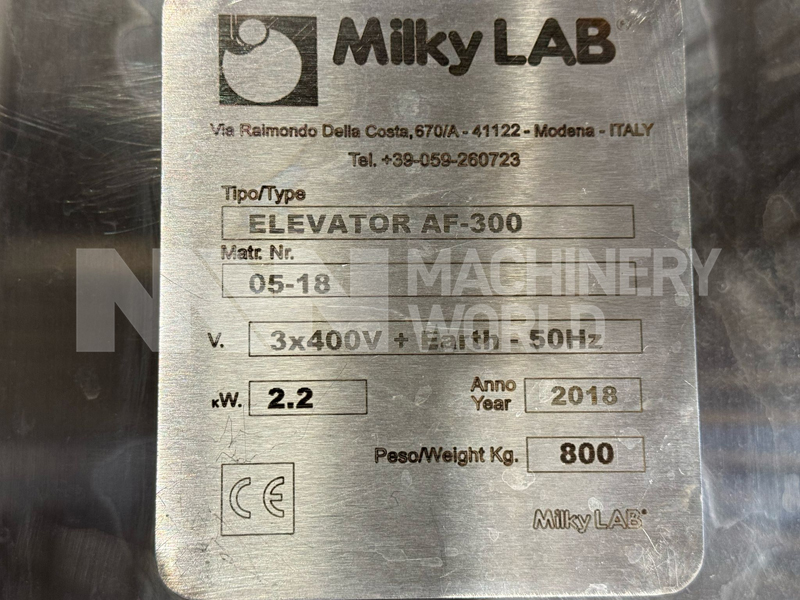

MilkyLAB Tilter Elevator with two 250L vats

-

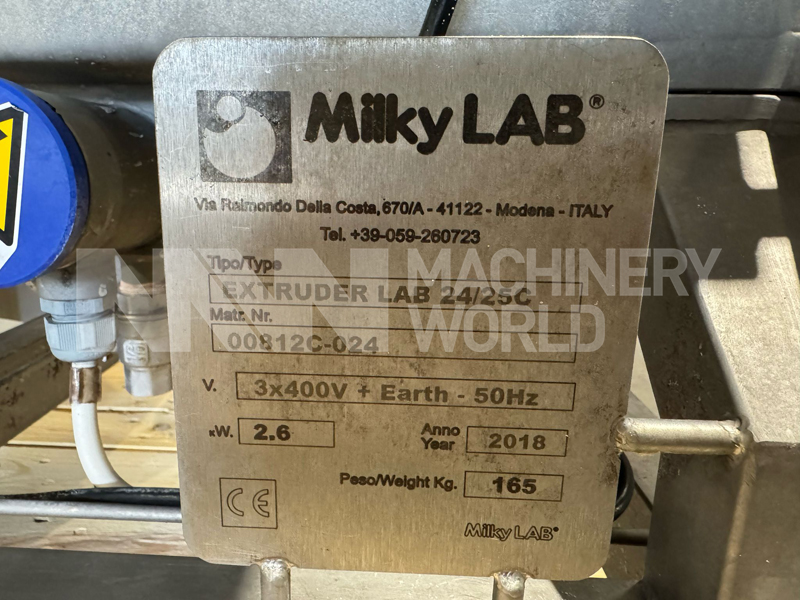

MilkyLAB 24/25C Extruder Lab for product transfer

-

MilkyLAB 24/25 for moulding and extruding the finished product

Manufactured in 2018, this line has an adjustable capacity of up to approximately 750kg per hour. The actual capacity varies depending on the product characteristics, moisture content, and moulding size.

The MilkyLAB system incorporates an innovative and highly efficient stretching process, offering significant operational benefits. It is both easy to use and economical, with operating costs reduced by approximately 50% compared to traditional hot water cooking and stretching machines. This reduction is achieved through decreased processing time and lower steam consumption.

Furthermore, the use of steam injection and a specially designed cooking vat increases the final product output by around 10% when compared to traditional cookers. This improvement is due to the elimination of fat loss and the complete absorption of added water during the process.

Thanks to these advancements, there is no need for a water purification system, as the design avoids water circulation within the system. Additionally, the cooker stretcher is equipped with an integrated washing system, eliminating the need for an external CIP unit.

The line is designed for use with fresh curd from cow or buffalo milk, as well as curd blocks and powdered ingredients.

Specification

- Make: MilkyLab, Italy

- Function: Cooker, Stretcher & Moulder/Extruder for Analogue Mozzarella

- Year of Manufacture: 2018

- Hourly Capacity: Adjustable to maximum of approx 750kg per hour (Capacity varies depending on the product characteristics, moisture and moulding size)

- Batch Capacity: 200kg

- Suitable for Pasta Filta Style Cheeses, Cheese Spreads and Analogue Mozzarella.

- The system is completely built in AISI 304/316 stainless steel and is totally arranged for the CIP automatic washing system.

- Heating: Direct Steam Injection directly into the Product or indirectly into the Jacket

- Cooker/Stretcher equipped with Litre-Counter and Automatic Weighing System with Load Cells for management of Recipes via PLC.

- Electrics: 3ph, 380V, 50HZ

- Total Installed Power: 16 kW

- Equipped with Siemens PLC

- Centrigual Pumps and Dosing Pumps: CSF Inox

- Plate Heat Exchangers: Sondex

- Sensors: IFM Electronic, SICK & Allen Bradley

- Safety Switches & Safety Relays: Allen Bradley

- Pneumatic cylinders, switches & valves: Festo & Pneumax

- Conductivity measurement instruments: Endress & Hauser

- Temperature Controllers: IFM

- Electric motors: SEW Eurodrive

- Push-buttons: Moeller

- Included Sections

- Lab 18 Cooker / Stretcher & Weighing System with Load Cells (Serial no: 01802-097)

- Tilter Elevator AF 300 with 2x 250L Vats (Serial number: 05-18)

- Lab 24/25C Extruder Lab Product Transfer (Serial number: 00812C-024)

- Lab 24/25 Moulder/Extruder (Serial number: 00812-040)

Country of Manufacture

Italy

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn