Description

The EURO PK IES EVOLUTION has been designed and built for the application of pre-threaded caps (namely screw caps) on bottles/containers. An orientation device selects the caps inside the hopper. A transfer disk, called “pick & place”, carries the caps under the closure head. The capping head follows the profile of a cam and picks the cap from the conveying device by a chuck with balls. The containers are driven by a conveyor belt inside the machine. The rotation of the entry star-wheel conveys the bottles on the closure carousel where they rotate till being under the closure head, that provides to the application of the cap on the container. Then, the application on the containers follows, by screwing the cap. After the closure, the exiting container is released, then there is a reset for the following closure.

Features

- Manufacture: Arol

- Model: Euro PK IES Evolution

- Function: Spiral accumulator conveyor

- Year of manufacture: 2013

- Serial number: 14147

- Pitch diameter: 540mm

- Number of heads: 15

- Direction of rotation: Counter-clockwise

- Nominal production: 24,000 bph

- Net weight: 3800kg

- Electrics: 415V/ 50Hz / 3 Phase

Includes

Pneumatic elevator

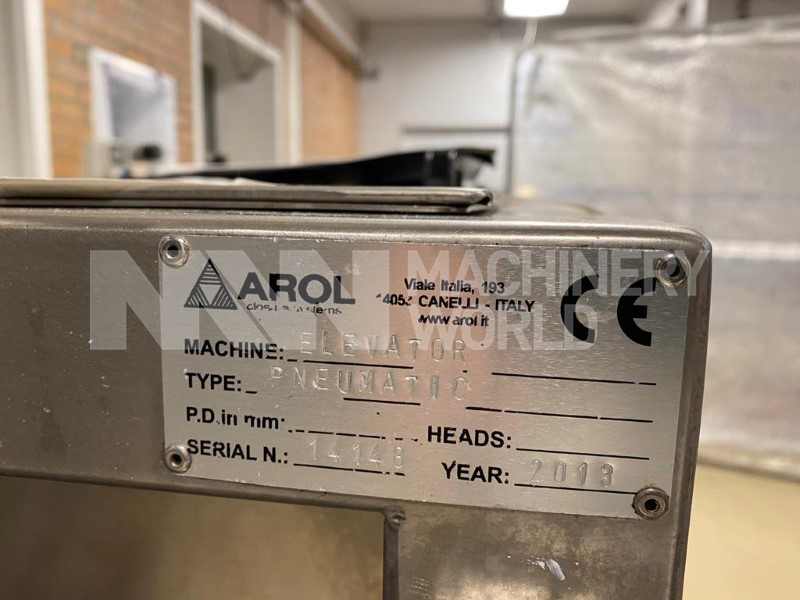

The elevator has been designed and built for the capper automatic loading. The constructive characteristics made it suitable to transfer plastic caps, corks, screw cap and aluminium cap. The hopper is the container where there are the caps. The discharge door allows to quickly empty the hopper, as an example, when it is necessary to carry out the format change. The caps lifting belt allows to transport materials from the hopper to the elevator dosing tank. The supplementary pipe allows the transfe of materials to the hoppers of the cappers (it can be used both in vertical and horizontal position). The interior tank belt allows the transport of caps from the hopper to the lifting belt. Fixed at the base of the elevator, the linear vibrator unit is placed under the caps stock hopper. The vibration that gives to the plate, linked to it, allows the caps to move and being charged on the lifting belt. The dosing tank is fixed at the end of the caps lifting pipe. It allows the discharge of caps into the cappers hoppers.

- Manufacture: Arol

- Model: Pneumatic elevator

- Year of manufacture: 2013

- Serial number: 14148

- Nominal production: 24,000 bph

- Electrics: 415V/ 50Hz / 3 Phase

- Total installed power: 5,37 kW

- Net weight: 800kg

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn