Description

Dosage: From the vertical funnel into the dosing flask, the butter is dosed into preformed molds on the 8-digit table. The funnel is equipped with a sensor to check the product level fitted.

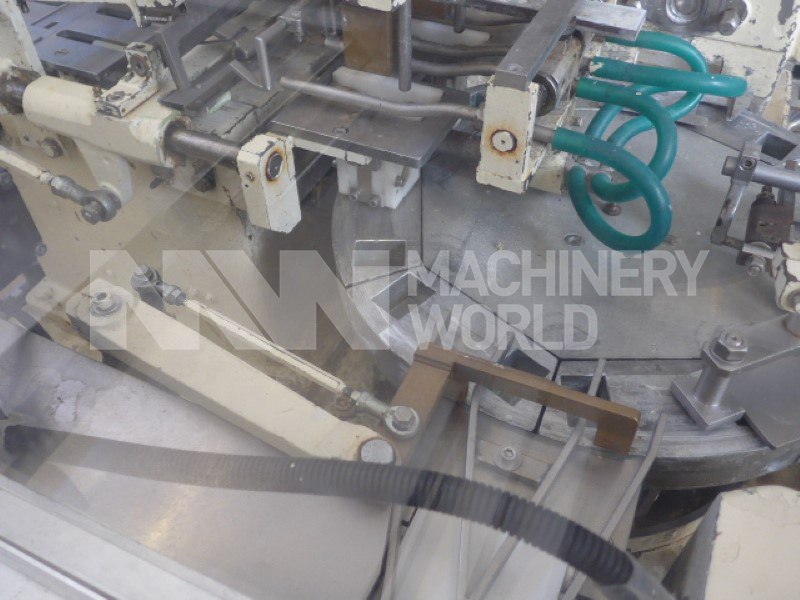

Impact system: “Envelope seal”

Box group: Attached to the outlet of the machine, for stacking one certain number of servings in blocks that are semi-automatic inserted into preformed boxes.

Product arrangement: 4 x 5 x 5 layers = 2kg

The spout is equipped with a sensor that in the event of a production jam, the machine stops.

Additional data:

Weight change is obtained by changing the portion size. This entails the replacement and adjustment of some parts on the machine and the basic dimensions of the portions are supposed to remain unchanged.

Foil centering group: Equipped with SICK type photocell for centering the printed film.

Ink coding device type: Metronic for coding a product code on the aluminium foil (max. 5-6 digits / letters).

Construction data:

All parts that come into contact with the product are made of stainless steel.

Protective covers: The machine is equipped with protective doors made of transparent material.

Microswitches stop the machine as soon as the doors are opened.

Colour: RAL 1013 Ivory

Machine provided with: Basic format 20 grams

Two format sets 10 and 15 grams

Boxing station with format 4x 5 x 5 = 2kg

Two format sets for nesting station 4 x 5 x 5 = 1.5kg

Features

- Manufacturer: Corazza

- Model: FB 220

- Function: Dosing and wrapping small portions of butter

- Year of manufacture: 1995

- Serial number: S740N

- Output: 280 servings per minute with an efficiency of 90% i.e. 252 servings per minute

- Portion weight: 10, 15 and 20 grams (rectangular portions) (See technical document link below for drawing)

- Product dimensions: 40 x 30 mm

Country of Manufacture

Italy

Download Technical Doc

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn