Description

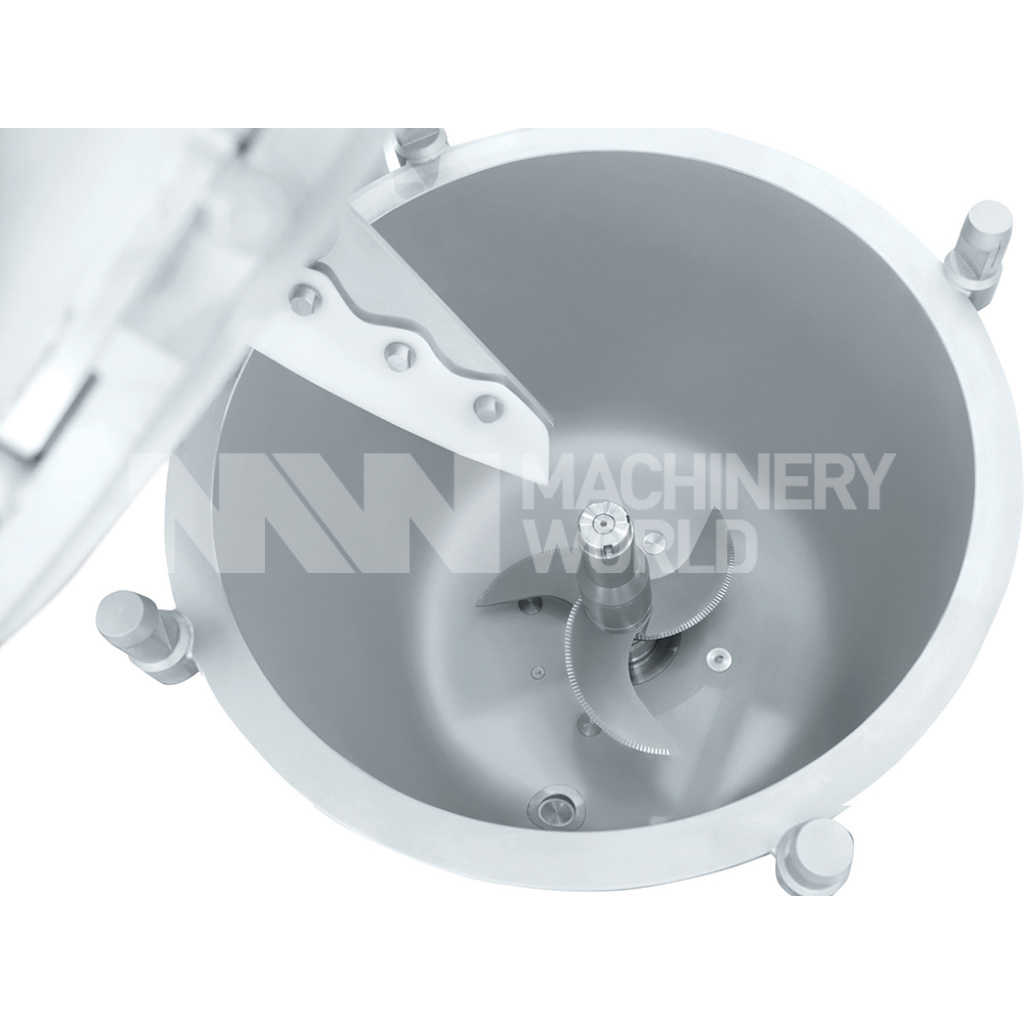

These Multifunctional Industrial Mixers (Cooker & Cooler & Mixer) are configurable for many different applications, some examples are processed cheese, dressings, sauces, baby food, confectionery fillings, almond paste, mayonnaise & ketchup and be able to handle different tasks such as mixing, emulsifying, heating up, cooling, grinding, emulsifying, size reduction, direct or indirect cooking under vacuum, deaerating (vacuum) and homogenizing.

Features

- Manufacturer: ROKK Processing

- Model: CCM 200

- Function: Universal mixing cooker

- Bowl capacity: 200 liters

- Year of manufacture: 2022

- Product processing capacity: 170 liters/ batch

- Batch time: 8-12 minutes

- Processing temperature: max 95 C

- Automatic tilting

- Automatic opening & closing of lid

- Direct steam injection

- Double jacket (Heating/ cooling)

- Vacuum pump (controlled negative pressure %)

- Discharge valve/ fitting

- PLC and touch panel

- Water flowmeter

- Axial face seal

- Main motor: 3 knives with 0-3000 rpm

- Frequency controlled main motor

- Scrapper’s motor: 2 scrappers

- Steam separation & filtration & pressure regulation station

- See ‘Technical Doc’ link for ROKK Brochure.

Optional

- Vacuum condenser for cooling & dehumidifying

- Processing temperature: max 125 C

- Buffer tank

- Discharge pump

- Flowmeter for oil dosing

- Flooring funnel

- Hoppers

- Inline mechanical homogenizer (micro-cut)

- Lifter

Advantages

- Short batch time

- Energy efficient

- Easy to integrate in a production line

- PLC process controlling system

- Component from the most reliable brands

- Configurable for many different applications

- Complete product emptying (Minimal losses)

Download Technical Doc

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn