Description

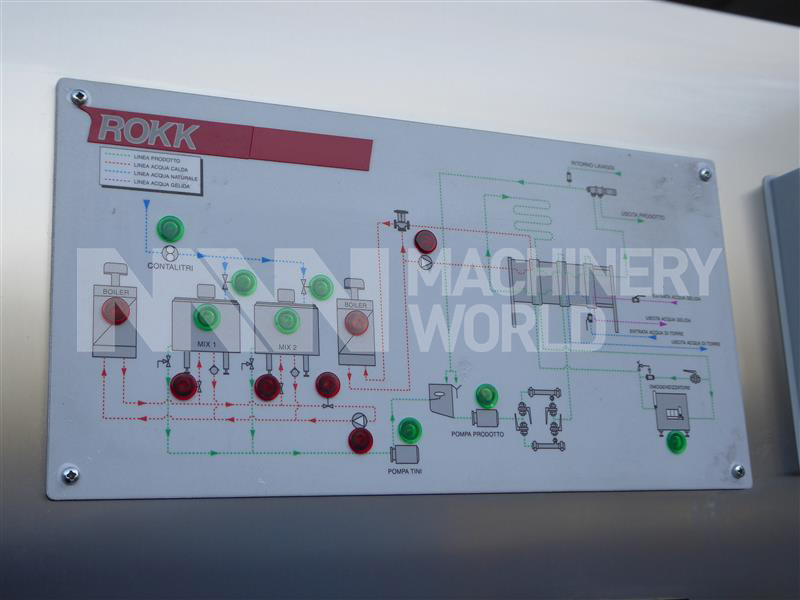

Ice cream processing plant designed for pasteurising, homogenising and cooling mix to +4°C ice cream mixes, by obtaining 75% of energy recovery. Year of manufacture: 2020. The condition is ex-demo (new & unused).

Features

A) Ice cream preparing tanks section:

2 x Pasteurising tanks made of stainless steel AISI 304 outer side, AISI 316 inner parts that come in contact with mixes. These tanks are supplied including agitators for blending raw materials, spray balls for washing unit. Thermometers for indication mix temperature. kW 2.2 each.

1 x Digital water counter

2 x Water solenoid valves

2 x Stainless steel three-way valves for mixes

1 x Stainless steel centrifugal pump 0.75 HP in order to feed ice cream mix to the balance tank of the pasteuriser

1 x Hot water centrifugal pump

3 x Hot water solenoid valves

Stainless steel platform with adjustable legs

Overall dimensions (Length x Depth x Height) 3350 x 2000 x 2000 mm

B) Pasteurization section:

1 x Balance tank cap. 100 Lt with lid

1 x Sanitary centrifugal pump made of stainless steel capacity of 1200 Lt/h for ice cream mix

1 x Stainless steel filter in order to prevent solids (such as seeds or lumps) entering the homogeniser

1 x Heat exchanger suitable for pasteurising 1200 Lt/h of ice cream mix, by following this thermal cycle

Product inlet 58°C

Energy recovery 75°C

Pasteurizing stage 85°C

Energy recovery 65°C

First cooling stage: process water/milk

Second cooling stage: cooling tower +29°C – Cooling tower water at +29°C 6000 Lt/h

Third cooling stage – chilled water at +1°C 8000 Lt/h

The holding pipe is sized for 40 seconds provided at the end of the system with a 3 -way diversion pneumatic valve.

1 x Flow mix process valve

1 x Electrical panel board provided with the thermal regulator, electronic temperature register including alarm control and switching.

Stainless steel platform with adjustable legs.

1 x Flow divert valve for washing

Overall dimensions (Length x Depth x Height): 2710 x 1800 x 2000 mm

Thermal capacity: 15000 Kcal/h for pasteurising boiler – water T. 88°C

65000 Kcal/h for pre-heating group boiler T. 70°C

(boilers supplied by customer)

Total electrical power: 10.5 kW

Voltage: 380 W / 50 Hz / 3 Ph

C) Homogenisation section:

1 x 2 stage homogeniser 1200 Lt/h

Working pressure: 230 Bar

Voltage: kW 11

Voltage: 380 W / 50 Hz / 3 Ph

Overall dimensions (Length x Depth x Height): 900 x 1200 x 1360 mm

D) Powder blender:

Powder System ROKK RPB 15000

Max flow capacity 250 ltr/min

Max Powder induction 10kg/min (depending on powder)

Pump Power Rating 5.5kW

Material 304 stainless steel

Flow control Manual Valve

Frame type Table type with provision to store the powder bag.

Hot water flow 4000 ltr/hr

Overall dimensions (Length x Depth x Height): 1020 x 850 x 1700 mm

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn