Description

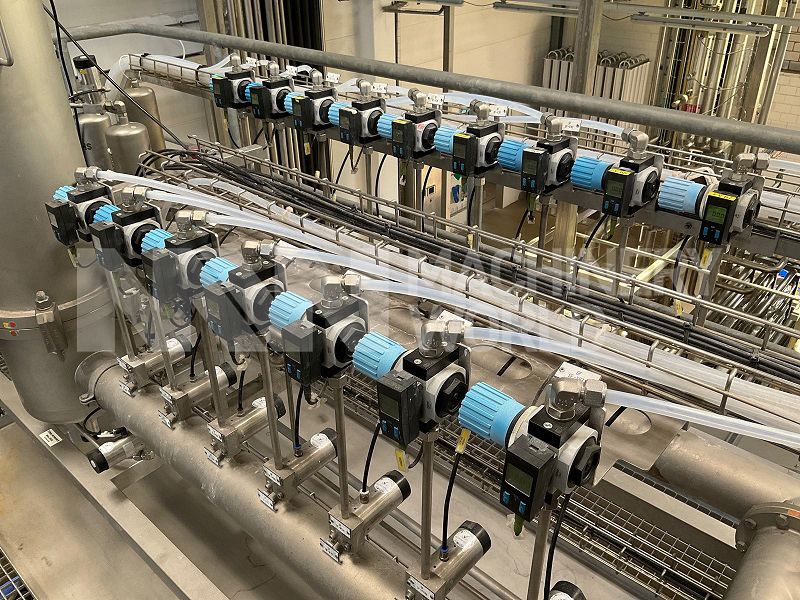

This is a used KHS Aseptic Filling Line (Year of Manufacture 2006) for PET bottles for sale, formats 330ml / 500ml, suitable for juices and soft drinks (carbonated 24.000 bp/h or non-carbonated 30.000 bp/h) with Siemens Control S7 year manufacture 2006 but undergone upgrade in 2019 and line includes KHS Cap Sterilizer, 16,100L Reiger Aseptic Sterile Process Tank with Mixer (Year 2006), 3,060L Reiger Aseptic Sterile Holding Tank (Year 2006), KHS Aseptic Filler, KHS CIP-SIP System, Control Systems, Labeling, Conveyors and Heat Shrink Wrapping including carry handle applicator, Tray Packer and Palletizing Robot.

Specification

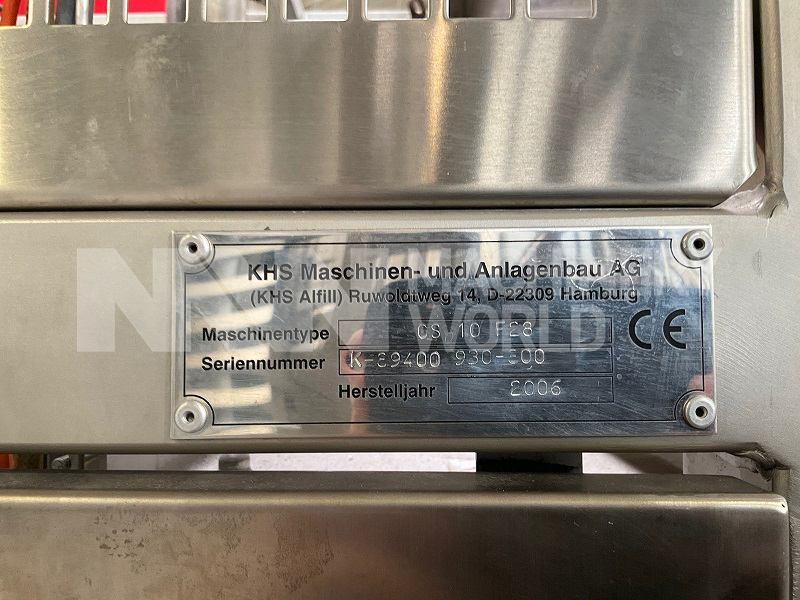

| KHS Cap Sterilizer 1 | SCS 8 Flatcap 28mm, Year 2006 |

| KHS Cap Sterilizer 2 | SCT 4 Flat 38 mm, Year 2006 |

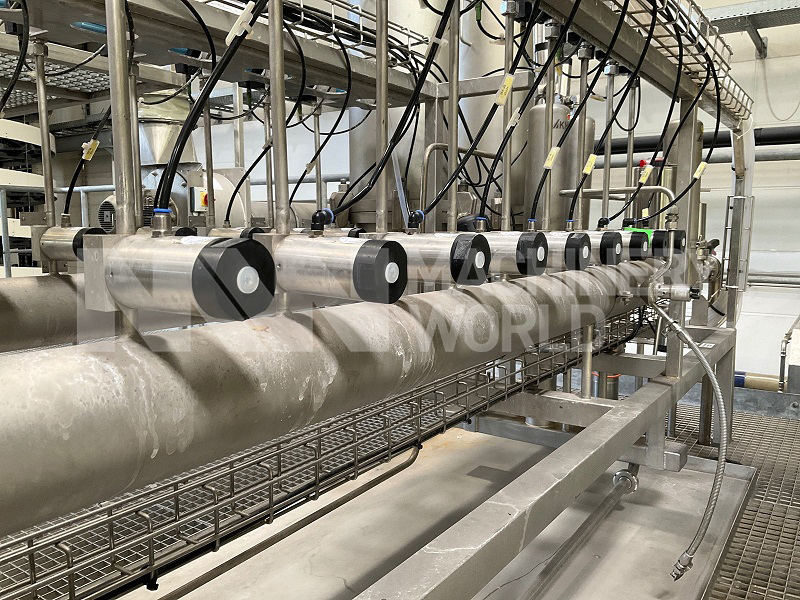

| KHS Aseptic PET Bottle Filler | Asmofill ACF 30-70-100-15, incl. supply units for peroxide, sterile air, foam cleaning, UPS, Year 2006 |

| Reiger 16,100 Ltr Aseptic Sterile Tank with Bottom Mixer | Volume 16,100 Ltr, Year 2006, Full Vac/4 bar, 140 deg C |

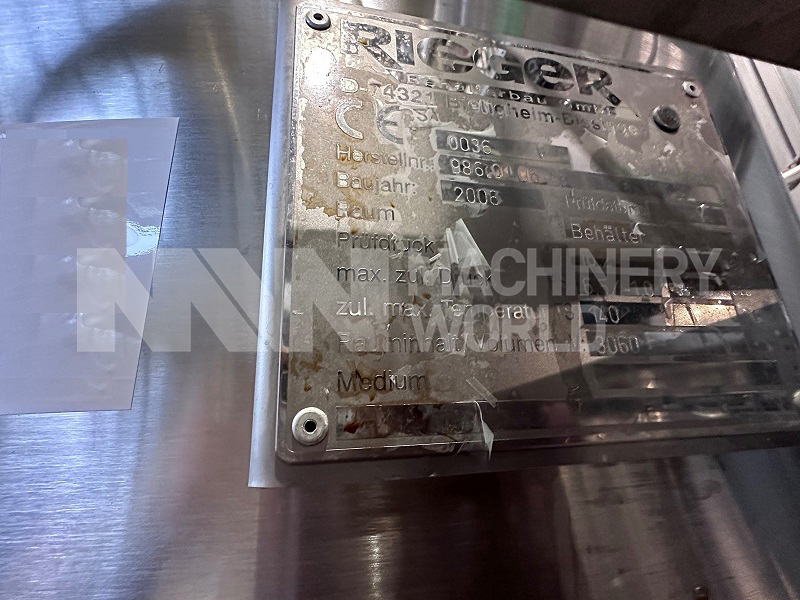

| Reiger 3,060 Ltr Aseptic Sterile Holding Tank | Volume 3,060 Ltr, Year 2006, 140 deg C |

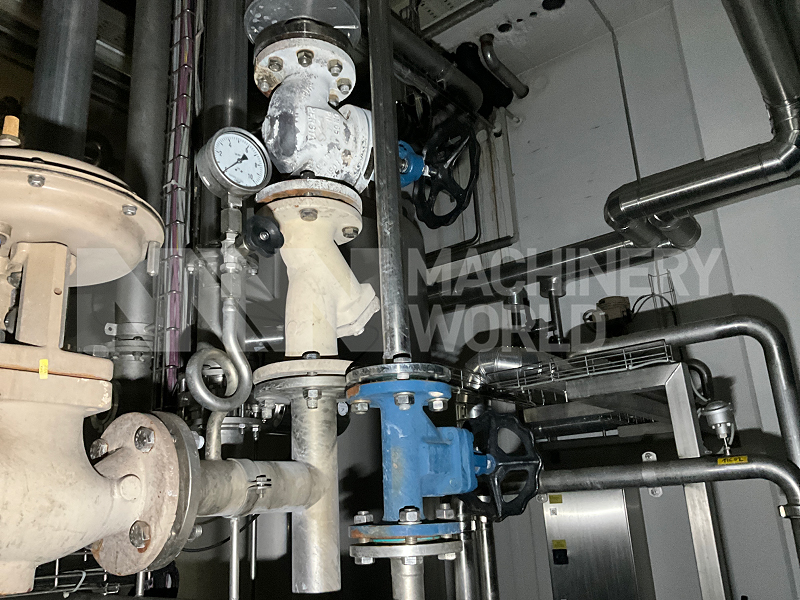

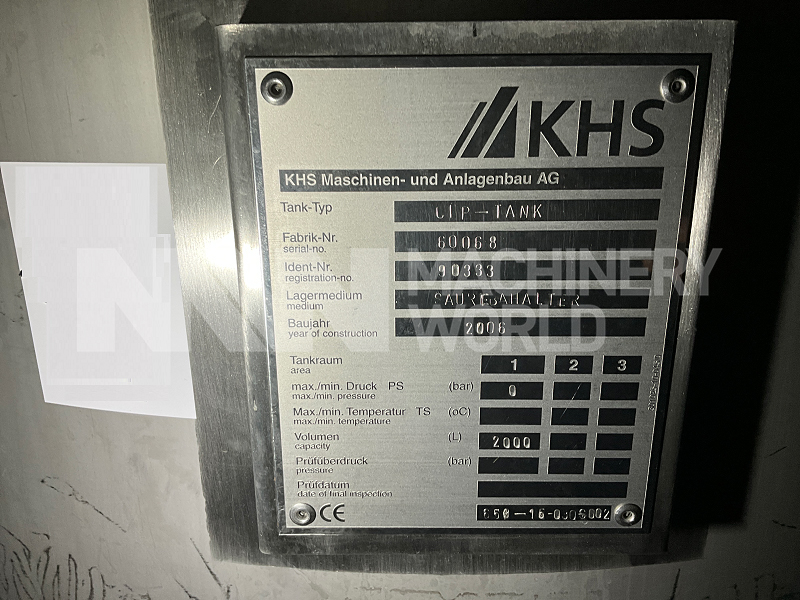

| KHS CIP/ SIP system | Innopro 1-500/2-3000/35 A, Year 2006 |

| KHS System for data acquisition and analysis | AIS MIDI, Year 2006 |

| KHS Cap and Fill Level Control System | METEC FMS BV, Year 2006 |

| KHS Labeling Machine, Hot Glue Labeler | Innoket – SE 60/120 2 RF 1HS PT |

| KHS Label Control System | METEC- ETK, Year 2006 |

| KHS Container Transport System | Innoline – BTR / P 30241/131, Year 2006 |

| KHS Tray Shrink Packer | TSP 050 V TPFO, Year 2006 |

| KHS Carry Handle Applicator (CarryStripMaster) | CSM 050-2, Year 2006 |

| KHS Tray Packer | TP 035 B, Year 2006 |

| Pulstronic Metal Detector | M-Pulse2 BD-HD 150×600 LPW Year 2018 |

| BBull Technologies Label & Code Inspection System | IMAGE 500/5000, Year 2017 |

| Terboven Aseptic Nitrogen Dosing Unit | Aseptik 2, Year 2006 |

| Treboven Sterile Air Filtration | Aseptik 2, Year 2006 |

| GEA Diesel Mixture Control System | DICON DICAR, Year 2006 |

| KHS Labelling Module | SK-EL-79, Year 2010 |

Approx Capacities/Output:

0,50 L. carbonated > EW-PET > 21.800 bottles/hr.

1,00 L. carbonated > EW-PET > 18.000 bottles/hr.

1,50 L. carbonated > EW-PET > 16.000 bottles/hr.

2,00 L. carbonated > EW-PET > 14.500 bottles/hr.

0,33 L. non-carbonated > EW-PET > 27.000 bottles/hr.

0,50 L. non-carbonated > EW-PET > 27.000 bottles/hr.

0,75 L. non-carbonated > EW-PET > 27.000 bottles/hr.

1,00 L. non-carbonated > EW-PET > 27.000 bottles/hr.

1,50 L. non-carbonated > EW-PET > 19.000 bottles/hr.

2,00 L. non-carbonated > EW-PET > 14.500 bottles/hr.

Additional Details:

Aseptic Filling Line brand new price in 2006 > EUR 13M

Running hours: Approx 80.000

Line has had full upgrade in 2019 and in the end of 2021 overhauled (replacing the drive technology, servo technology and aseptic parts) at 76,000 operating hours.

NOT INCLUDED: PET Bottle Preform Blower & Moulder

Country of Manufacture

Germany

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn