Description

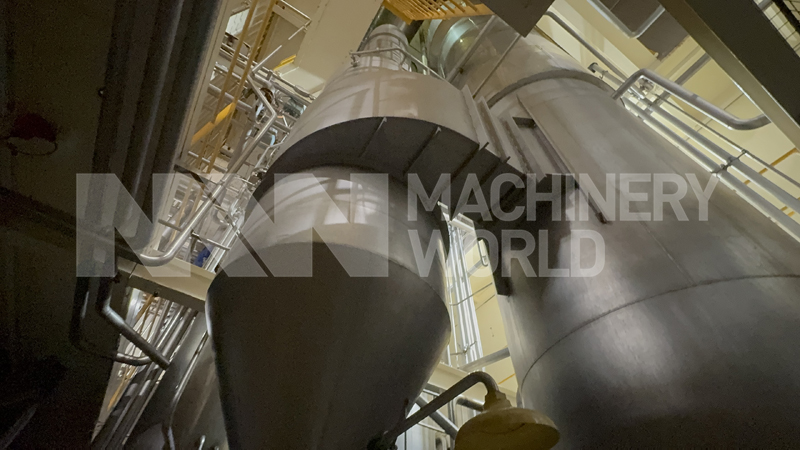

This pre-owned Stork 4-Effect MVR Evaporator Concentrator Plant is a highly efficient system designed specifically for concentrating skim milk in dairy production. It works by using a method called Mechanical Vapor Recompression (MVR), combined with a multi-stage evaporation process (four stages or “effects”), to remove water from the milk in the form of steam. This process increases the milk’s solid content. The equipment is still installed and is currently available for immediate sale.

Mechanical Vapor Recompression (MVR) represents an exceptionally energy-efficient technique employed in industrial evaporation processes, particularly within the dairy and food sectors, aimed at concentrating products by extracting or evaporating water. In MVR systems, liquid water is vaporized through heat, typically supplied as steam from a boiler. The generated vapor is subsequently compressed by a mechanical compressor, which elevates both its temperature and pressure. This reheated vapor is then utilized as the main heating source in the evaporator, eliminating the need for additional steam from the boiler. Consequently, this method facilitates a closed-loop system that recycles its own energy, significantly minimizing overall energy consumption.

Note: Download brochure available on ‘Technical Doc’ link and specification shown below, are for information purpose only, as mentioned on manufacturer’s brochure, and the actual machine’s capabilities and efficiencies might vary.

Evaporator Concentrator Features

- Manufacturer: Stork, The Netherlands

- Function: Multi Stage MVR Evaporator Concentrator Plant (Mechanical Vapor Recompression)

- Type of installation: Falling Film Evaporator Concentrator: 4x Effect MVR

- Application: Whole Milk, Skim Milk Whey etc

- Vapour Compression: Mechanical Vapour Recompression

- Vacuum System: Liquid Ring + Vacuum Pumps

Evaporator Specification

- Skim Milk

- Feed In Rate: 29,084 kg per hour

- Solids in Feed: 8.8%

- Temperature of Product to be Concentrated: Between 4 and 16 deg C

- Water Evaporation Rate: 23,965 kg per hour

- Concentrate Feed Out Rate: 5,119 kg per hour

- Solids in Concentrate: 50% Total Solids

- Temperature of Concentrate on discharge: 65 deg C

- Pasteurising Temperature: 74 deg C (Low Heat) & 90 deg C (High Heat)

- Heating Temperature: 72 deg C to 90 deg C

- Product Boiling Temperatures:

- Boiling Temperature Effect 1: 72 deg C

- Boiling Temperature Effect 2: 69.5 deg C

- Boiling Temperature Effect 3: 64.3 deg C

- Boiling Temperature Effect 4: 65.1 deg C

- Consumption

- Pasteurising Product upto 90 deg C: 515 kg per hour

- Compressor Power: 350Kw

- Pump(s): 69Kw

- Detailed pictures & video available of the full line upon request

- Please refer to ‘Technical Doc’ link for detailed spec of Evaporator/Concentrator

Country of Manufacture

The Netherlands

Download Technical Doc

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn