Description

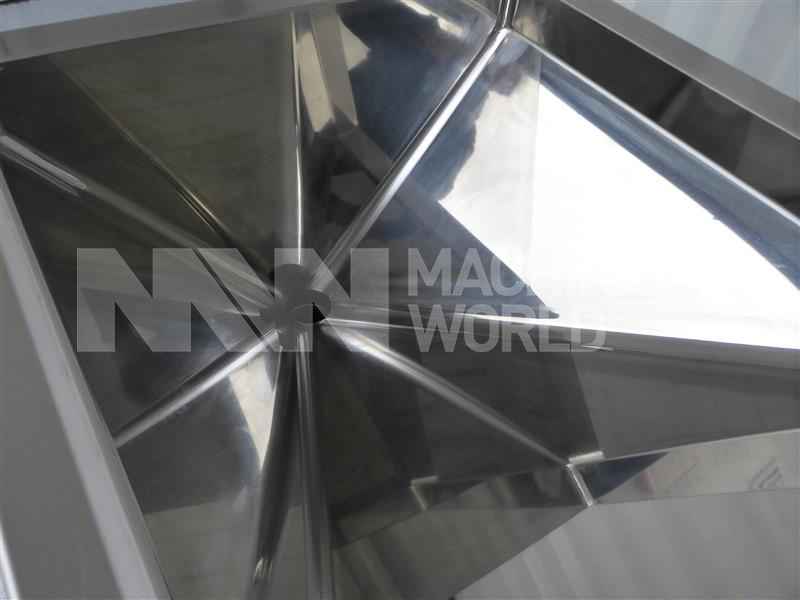

A ROKK powder blender will enable the customer to produce a higher quality, more consistent and homogenous mix as well as delivering improved operator ergonomics. The RPB15000 utilises a ROKK liquid-ring vacuum pump connected to a powder table with chute and valve.

During the heating process, the mix passes through a transfer loop from the mixing tank and back again at high velocity. This high velocity transfer creates a vacuum which is utilised to induct the powder ingredients into the flow of mix creating an improved emulsion, better mixing with a more consistent finished product.

Specifications

| Powder System | ROKK RPB 15000 |

| Max flow capacity | 250 ltr/min |

| Max Powder induction | 10kg/min (depending on powder) |

| Pump Power Rating | 5.5kW |

| Material | 304 stainless steel |

| Flow control | Manual Valve |

| Frame type | Table type with provision to store the powder bag. |

| Dimensions cm | 102w x 85h x 170L |

Primary benefits

Simple operation: Each machine in the Batch Mix Plant range is fitted with an easy to use manual control system to provide complete yet simple control throughout the pasteurisation process.

Compact and easy to install: Despite the large capacity of the mix plants, each is incredibly compact and due to the clever design, and as a result is quick and simple to install.

Environmentally friendly: The mix plants are environmentally friendly as rather than heating the mix in the large tanks, it is heated during the pasteurisation cycle when it passes through the plate heat exchanger, substantially reducing the power required to perform the process.

Well engineered and reliable: The internal mechanics, quality components and premier materials used throughout the range seamlessly combine to produce a machine that can be depended on day-in, day-out.

CIP washable: Due to the intelligent design and layout, each of the batch mix plants is simple to clean and maintain.

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn