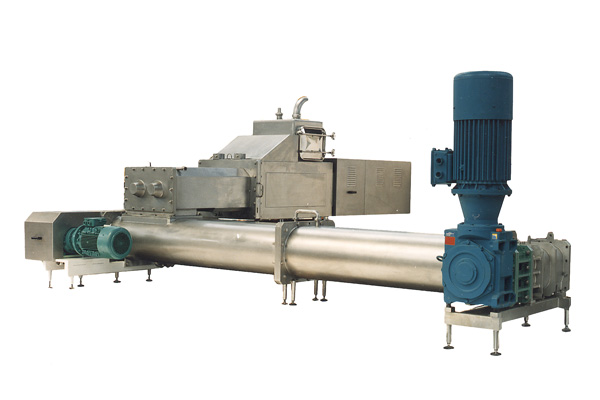

For the reconstitution of milk or cream, and for the MGLA production, SIMON FRÈRES has developed continuous fat melting systems.

Fresh butter can be directly pumped to the melting tube where the number of tubes is calculated according to specific needs of each project (outlet temperature, capacity, …).

Butter or other fat block must first be cut and then pumped to the melting tube. See our Butter Range – Reworking

The main advantages:

- Gradual heat transfer in the absence of air ensures maximum product quality.

- Precise control of the melted product final temperature.

- Small temperature difference between the outlet product and the heating media.

- Carefully designed to ensure hygiene and product security.

- Wide range of capacity.

Shipping

Need help with dairy machinery transportation?

Every month we export machinery to customers all over the world.

Offering competitive prices for air, sea or road freight, we can crate machinery and process all export documents to ensure the process is quick and stress free.

To enquire about shipping, just give us a call on +44(0) 1455 220 179

Spares

Need spares for this machine?

Parts Station stocks a host of spare parts for dairy and ice cream machinery.

With international shipping and door-to-door courier services, Parts Station can supply them quickly before any major disruption occurs. Click below to go to the site.

Have a machine like this to sell?

We make quick decisions and pay the best prices in cash for good quality, used dairy and food processing machinery, from single machines to complete plants.

To sell your machinery, just give us a call on +44(0) 1455 220 179 or

email us

Reviews

To read or send us your own review of our products and services, please click below.

Read our reviews

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn