A Legacy of Excellence – The History of Morelli’s

Morelli’s has been delighting customers for over a century, with its roots tracing back to the early 1900s in Casalattico, Italy. Seeking better opportunities, members of the Morelli family emigrated, with Peter Morelli first working as a glassblower in Paris and London before joining his brother Giuseppe (“Joe”) in Ballymena, Northern Ireland, where Joe had opened a café.

In 1911, Peter set up his own shop in Coleraine’s Stone Row, selling fish and chips, confectionery, tobacco, and, most importantly, ice cream. Recognising the growing love for their handcrafted ice cream, the family expanded their business, culminating in the opening of ‘The Ice Palace’ in Portstewart, which became a beloved destination.

In 1925, Peter invited his nephew Angelo from Italy to join the business. Angelo quickly took to the trade, purchasing the Portstewart shop in 1928 and dedicating himself to perfecting the art of ice cream making. He and his wife, Anastasia, grew the business while raising their three sons, Nino, Corrado, and Guido. Despite the hardships of World War II, including Angelo’s internment and the family’s separation, their passion for ice cream never wavered. After the war, Morelli’s expanded across the Causeway Coast, becoming a household name in Northern Ireland. Today, five generations later, Morelli’s continues to serve award-winning flavours, keeping the family’s tradition alive by using only the finest ingredients to create the same creamy, indulgent ice cream that has been loved for generations.

What Makes Morelli’s a Champion of Champions?

Morelli’s unwavering commitment to excellence has solidified its status as a champion in the ice cream industry. Their product is renowned for its consistency, and the quality of their dairy ingredients is second to none.

Arnaldo puts it best:

“With the combination of great quality dairy ingredients, ROKK Processing’s fantastic machinery and our excellent production team, it’s lovely that our passion for making great tasting ice cream has been recognised.”

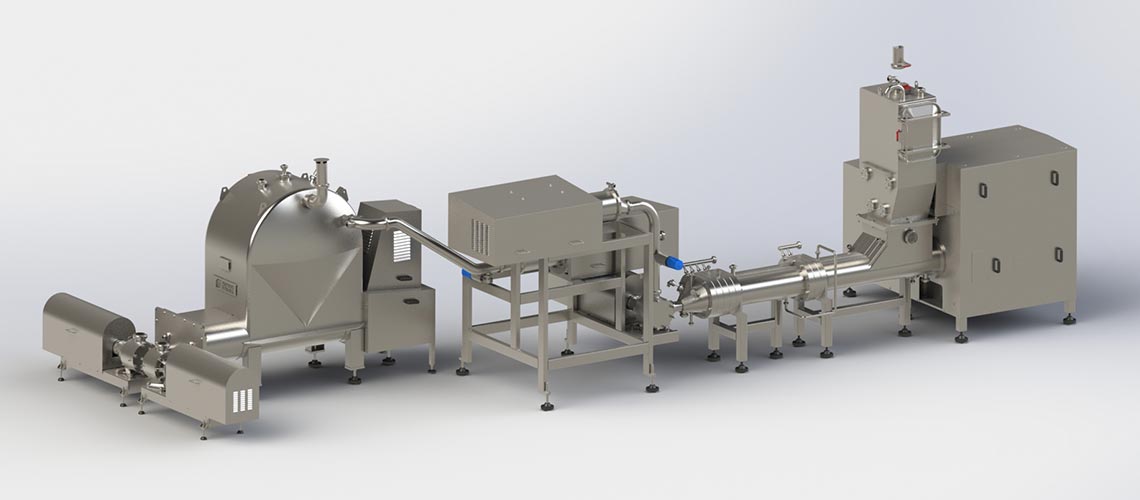

This dedication to quality is complemented by their collaboration with ROKK Processing, whose state-of-the-art machinery ensures precision and efficiency in production.

A Partnership Built on Trust and Respect

The relationship between Morelli’s and ROKK Processing spans over two decades, marked by mutual respect, trust, and a shared passion for innovation.

“We have always been delighted with the service we receive from ROKK Processing. There’s a mutual respect and trust from one family business to another, which has helped establish a strong rapport.”

In 2022, this collaboration reached a new milestone with the introduction of additional, new ROKK Processing equipment, further enhancing Morelli’s production capabilities.

Morelli’s also utilises ROKK Processing’s ice cream machinery as an essential part of their production line. These machines allow them to produce ice cream at higher volumes without compromising the quality they are known for. ROKK Processing’s equipment features advanced systems that ensure a continuous and smooth flow of production, while maintaining the perfect texture and consistency in every batch. Designed for both high production capacity and energy efficiency, these machines offer the ideal solution for Morelli’s growing demand.

The camaraderie between the teams exemplifies the essence of a family business relationship, contributing to the continued success of Morelli’s Ice Cream.

With a combination of top-tier ingredients, expert production, and cutting-edge machinery from ROKK Processing, Morelli’s continues to set the standard for excellence in the ice cream industry.

Founded in 1856, Simon Freres are experts in the field of modern high-performance machines for dairy and butter industries with a range of continuous churns from 120kg to 12T per hour.

Founded in 1856, Simon Freres are experts in the field of modern high-performance machines for dairy and butter industries with a range of continuous churns from 120kg to 12T per hour.

Instagram

Instagram YouTube

YouTube LinkedIn

LinkedIn