The Machinery World Service Team, L-R Martin Alexander, Russell Jex and Chris Wilson. Photo courtesy of Chris.

At Machinery World, it’s the small things that make a big difference: the minute attention to detail that goes into every repair, the bespoke tools developed to solve problems more efficiently, and the size of the service department, where a team of just three ensure that around 300 ice cream machines are kept in tip top running order each year.

The service department is led by senior engineer Russell Jex, a refrigeration focused electrical, mechanical and maintenance engineer who has been at Machinery World for six years – and it’s the variety of the job that keeps him smiling as he roars to work on his SUZUKI SV650S motorbike.

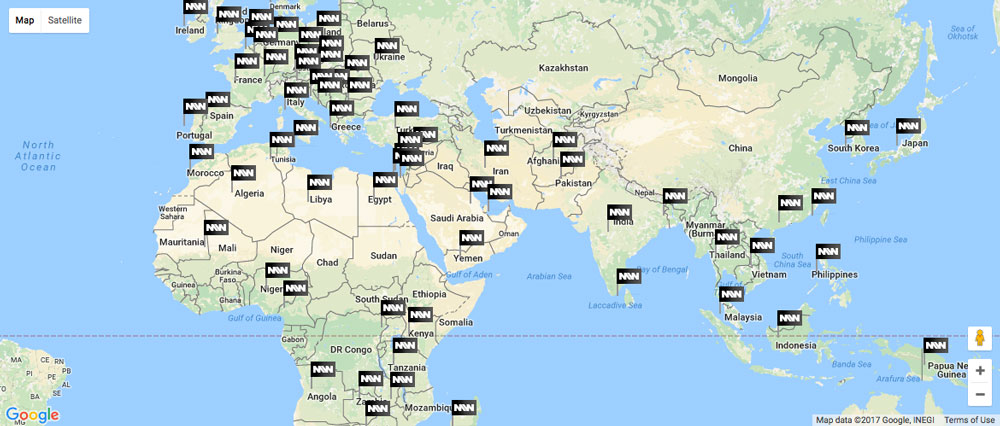

No two days are ever the same in Russell’s job and he’s frequently out on the road servicing customer’s machines on site, from Macclesfield to Mauritius and Guildford to Ghana.

“Along with an on-going programme of servicing contracts, commissioning and training on brand new machines, we also try to get out and fix unscheduled breakdowns the very same day, or at the latest, the day after,” explains Russell, “which means great teamwork is essential, as we schedule jobs between us to ensure we provide the best possible service to all our customers.

“There are 30 – 40 different manufacturers, each with 10 – 15 models of machines – and then there’s the different years too, of course, with upgraded components, so we have an extensive library of manuals – both physical and in our heads.

“Whilst the principles of the machines are the same, they all dismantle differently and there’s a wide range of things that can go wrong,” he continues. “I love the challenge of diagnosing the fault, then fixing it as quickly as possible so our customers can get on with the serious business of making ice cream – particularly honeycomb, my personal favourite.”

In fixing faults efficiently, the team have a secret weapon – the awesome ability of Martin Alexander to make unique tools and equipment from a simple drawing or concept.

“I’ve been at Machinery World for four years now, and put my background in engineering, welding and fabricating to good use creating tools to help us do the job better and faster,” explains Martin. “We discuss jobs between us in the workshop, and if one of us has had a tricky experience, say removing an old, crusted part, then I’ll design and build a specialist tool to make the job easier and quicker the next time around.”

Martin’s unique toolkit is supplemented by the more traditional tools – and the teams’ mobile workshop vans.

“We always try to fix the problem before we leave site,” says Chris Wilson, the newest member of the team at eight months in, who came to the workshop to set up an apprenticeship scheme with North Warwickshire College, and decided it was actually the perfect job for him. “So we’ll take a full kit of parts, supplied by our own spares department, Dairy Bits, for the machine we’ll be working on. Our vans are also loaded with vices, heavy tools and, of course, our Martin specials and we pride ourselves on finding solutions and getting the customer up and running again the very same day.”

The only exceptions would be if a major part had failed – but even under these circumstances, the intrepid trio won’t take no for an answer as customer Sebastian Parker at Callestick Farm in Cornwall can testify:

“There was a crack in the dasher in my Soren CS1500 which would have meant a replacement part, but Russ and co suggested we chop it in half and re-weld it. The dasher spins quite fast, so it had to be welded perfectly straight, right there on the farm.”

The farm’s own welder Ray carried out the repair under the watchful eye of Russell – and two years on, the machine has once again flown through its annual service.

So with no two days the same, what do each of the three Machinery World engineers like best about their jobs?

“For me it’s the customer satisfaction, the relationships we build and the service we can provide,” says Russell. “Because there’s only three of us, and we work specifically on post-pasteurisation machinery, we know our customers, their machines and the machine history inside out. Our customers will always see a familiar face and have the reassurance that if their machine can be fixed, then we’ll fix it.”

“I like the variety of work, and the new skills I’m learning every day,” says Chris, “but the best thing of all is the atmosphere and camaraderie across the whole of the workforce. This is a family business and that really comes through, as when a job needs doing, be it strapping machines onto a container or jet washing the vans and warehouse in advance of a customer visit, we all work together as a team.”

“It has to be the freedom Machinery World give me to design and create tools and gadgets which help us, and our customers,” says Martin. “One of my recent projects has been to design and build a flexible filling arm, which both supports the filling pipe and takes all the strain off the person, enabling the operative to put the tub on the table and move the pipe around instead. The pipe is self-supporting off the freezer and, whilst I designed it originally for the ROKK 600, the fixings are universal, so it can be used on all continuous freezer models.

“The job satisfaction when you see one of your creations being used by customers is second to none.”

To find out more about the service department, visit www.machineryworld.co.uk/machinery-service

Twitter

Twitter Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn