Listen to Greg Jenner and his guests Dr Annie Gray and Richard Osman on BBC Radio 4 to get the inside scoop on the history of ice cream.

Listen to the discussion on BBC Radio 4 here

Listen to Greg Jenner and his guests Dr Annie Gray and Richard Osman on BBC Radio 4 to get the inside scoop on the history of ice cream.

Listen to the discussion on BBC Radio 4 here

On 15 September Channel 5 broadcast Michael Portillo’s south west coast path adventure – his final stretch in Cornwall, and takes in a coastline of coves, sub-tropical garden and smugglers’ creeks.

He also visited Roskilly’s Ice Cream a Machinery World customer who has a ROKK RFE 1200/2 twin barrel continuous freezer and ROKK RIF 1500 ingredient feeder which Michael is filmed using to fill some ice cream tubs.

Michael Portillo is a British journalist, broadcaster and former politician. His broadcast series include railway documentaries such as Great British Railway Journeys and Great Continental Railway Journeys. A former member of the Conservative Party, he was Member of Parliament (MP) for Enfield Southgate from 1984 to 1997 and Kensington and Chelsea from 1999 to 2005.

ROKK’s RFE continuous freezer range comprises of 13 machines, each varying in size and power, but all being ideal for use in small laboratories all the way up to large factories. Equipped with self-contained Bitzer freon ‘refrigeration’ compressors, each machine in the RFE continuous freezer series has been designed for easy installation and increased mobility in the factory.

The ROKK RIF 1500 ice cream fruit feeder is a durable and highly flexible machine which allows for flavour enhancing clusters to be uniformly and consistently added to a continual flow of ice cream without risk of causing time consuming blockages.

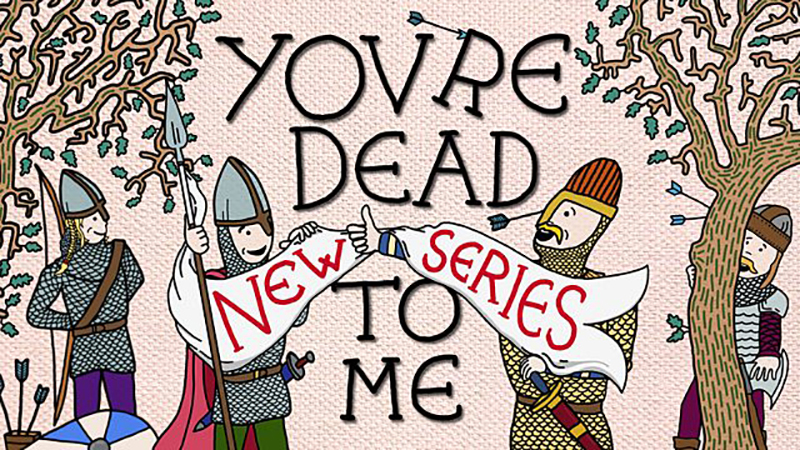

“Well over a third of consumers are treating themselves now more than ever”

While scores of Brits embraced healthier lifestyles during lockdowns, others boosted their morale by tucking into treats.

That’s shown by the extra 54 million litres of ice cream that went through the tills last year, adding £226.1m to the take-home market [Kantar 52 w/e 27 December 2020]. And, as consumers sought out comfort in calories, indulgent lines were the biggest winners. To sum up the nation’s mood: Magnum was the fastest-growing brand and better-for-you sensation Halo Top was the fastest-falling [Nielsen].

“Well over a third of consumers are treating themselves now more than ever, and are looking for comfort and indulgence,” says Kat Jones, marketing manager at Häagen-Dazs.

So where does all this indulgence leave low-calorie lines? Was ‘healthy’ ice cream just a flash in the tub? And with lockdown restrictions easing and people venturing out, what’s the forecast for ice cream this year?

“As the pandemic took hold there was a really big resurgence of growth in indulgence”

Fast-becoming a true alternative to dairy, oat milk could be the biggest thing to shake up the industry ever.

If you haven’t yet tried any oat milk products yet, prepare to be pleasantly surprised by this healthy dairy alternative.

We’ve seen almond, coconut, and cashew milk in supermarkets for years, but now oat milk is the latest dairy-free alternative to trend, cropping up everywhere from local coffee shops to select Starbucks stores and supermarkets. It’s made from steel-cut oats or whole groats that are soaked in water, blended, and then strained, with an end result that’s creamier than most nut milks. And while you may just be getting used to adding it to your morning coffee or requesting it in lattes, catch up—the latest oat milk innovation is already here, and it can be found in the freezer aisle.

Oat milk’s entry into the market is significant. Back in February, So Delicious Dairy Free launched what it claimed to be “the first-to-market” frozen oat milk desserts in three flavors: peanut butter & raspberry, oatmeal cookie, and caramel apple crumble, which are all dairy-free, gluten-free, and vegan. And recently, Oatly, the Swedish oat milk brand that’s quickly taken the Western World by storm, announced an ice cream line of its own. (Also dairy-free, gluten-free, and vegan, as well as nut-free, soy-free, and kosher.)

A vegan milk made from pulped oats may not sound like a tasty proposition, but Oprah Winfrey, Jay-Z and Natalie Portman would beg to differ.

The celebrities are among the backers of Oatly, the maker of plant-based cheese, ice cream and other “dairy” products that listed in New York recently.

Oatly was founded in the early 1990s by Rickard Oste, a university professor, and his brother Bjorn. Until recently, its milk substitute was little-known outside hipster enclaves.

Thanks to quirky advertising, though, Oatly is escaping this niche. In February 2021, the company spent an estimated $5 million on a television advert during the Super Bowl, one of the ad industry’s premier slots. It featured Toni Petersson, Oatly’s chief executive, standing behind a synthesiser in the middle of a wheat field singing the slogan “wow, wow, no cow” on repeat. The jingle was pure earworm, but it achieved its goal. The ad caused a stir on social media.

Oatly has been floated on the Nasdaq stock exchange in New York at a price of $17 a share, valuing the company at nearly $10 billion.

The group, based in Malmo, raised $1.4 billion, including $1.1 billion in new shares and $335 million for selling nvestors.

Toni Petersson, its chief executive, used the listing to cut his holding in Oatly from 9.9 million shares to 8.6 million, collecting $22.1 million and leaving him with a 1.5 per cent stake worth $146 million.

With more than 60 years of experience, Vezzadini is one of the world’s leading manufacturers of packaging machines for margarine, butter and fresh cheese.

Vezzadini started in 1955 and since then has stood out for its great technical capacity and constant desire for innovation.

Vezzadini’s business began by developing the first automatic packaging machine capable of dosing & wrapping butter in a perfectly cylindrical roll shape. Over the years many new packaging machines have been designed, always characterized by the inventiveness and imagination typical of Italians.

I scream, you scream, we all scream for ice cream. However, have you ever thought of breaking your regular breakfast routine and indulging in something that is generally considered as a dessert?

We know how unusual that may sound, yet this is true. According to a study held at Kyorin University in Tokyo, those who eat ice cream for breakfast are comparatively smarter than those who do not. This might be the most delightful piece of news you’ll ever hear.

How does it work?

Known to have an ‘awakening’ effect on the mind when eaten in the morning, ice cream immediately shocks the brain and makes it active, helping to increase your mental capacities. In other words, soon after waking up in the morning, having ice cream can significantly boost your mental health, as well as perk up your brain to a level that makes you more mentally alert throughout the day.

What did the study claim?

The researchers at Kyorin University, Tokyo had conducted several experiments, in order to provide a solid ground to prove this unusual study. A group of subjects were given ice cream right after waking up in the morning and were compared to another group whom was not given the ice cream. Upon waking up, the subjects who had eaten ice cream in the morning performed better throughout the day, as a result of being more mentally alert. The researchers had also carried out another experiment, in order to address the individuals who were sceptical of the ice cream theory, stating that it was purely down the cold effect of the ice cream. For this reason, the researchers had decided to give cold water to the subjects without ice cream in the morning. Despite these subjects performing better than last time, they were still outshined by the subjects with the ice cream.

Breakfast Vs no breakfast

It is well-known that if you do not have breakfast, you may find yourself not being as productive as those who do eat breakfast on a regular basis. When indulging in ice cream for the morning meals, it is all down to the level of glucose in your daily breakfast. According to a renowned nutritional psychology researcher, the foods containing high glucose level significantly amp up one’s mental capacities, in comparison to not eating at all.

Ice cream & happiness

There is something about ice cream that we just cannot stop loving. Ice cream is known to trigger positive emotions in the human mind and activates the pleasure spots in the brain. Of course going over the top with calories in the form of sugar will not benefit you in the long run, though if you are heading to an important job interview or perhaps a date, a spoonful of this sweet happiness won’t harm anyone.

All ice cream, gelato and sorbet products naturally have a percentage of air. Without air, they would be too dense and hard, lacking the beautifully smooth texture which you associate with quality a product.

Air increases the volume of the finished product, you probably already know this increases profit, but obviously, too much air can lower the quality of the product considerably.

On average, one litre of liquid ice cream mix before being frozen weighs approximately 1 kilo, the same weight of frozen mix will no longer fit in a 1 litre container, it now requires a 1.4 litre container due to the increase in volume due to the air content. As such, frozen ice cream products are more often sold by volume rather than their weight.

All frozen products have a different percentage of air, typically but not definitively some examples are:

Scoop Gelato – Typically 25-30%

Scoop Ice Cream – Typically 50-60%

Soft Serve Ice Cream (gravity machine) – Typically 30-35%

Soft Serve Ice Cream (pump machine) – Typically 60-80%

We have produced an Overrun Calculator which you can download here to help work out your own overrun.

Teknoice is a leading Ice Cream Machines manufacturer, offering a complete range of equipment, from stand-alone machines to complete layouts.

The company was started in 1992 and has grown into an international company selling worldwide. Teknoice has over 1200 clients in almost 100 countries worldwide, with 5 offices.

We are now the appointed UK Agency for Teknoice Ice Cream Machinery and look forward to offering the complete range of new ice cream machines including the superb new ‘Deep Ice’ machine which offers a superior ice cream product by operating at -10 degrees to produce less ice crystals giving a smoother, more palatable texture.

See the complete range of Teknofreeze ice cream machines here

We’d like to thank everyone for their business, support and assistance during what has been an unprecedented time for us all.

Wishing you and your family a restful Christmas break, we hope you stay safe and we look forward to some normality re-emerging next year.

From everyone at Machinery World

Combining the best of the old with the best of the new can give you outstanding results, as just one mouthful of the delectable Handmade Ice Cream Company premium selection will testify: produced using a combination of new and refurbished equipment from Machinery World, the mouth-watering flavours bring the skills of a former pastry chef right into your tub.

After fifteen years as a pastry chef in top hotels, Steven Darvill started a wholesale ice cream business with a difference, using his patisserie expertise to bake perfect cakes – then crumb them down to create the finest ice cream recipes. Eight years on, he has expanded production and also opened his first retail unit in Ulverston, Cumbria.

My business ethos is to make ice cream as a chef would make it if they had the equipment and the time to craft it themselves,” explains Steven. “Combining old skills with new, plus, of course, the finest 100% natural ingredients, I create around 35 – 40 bespoke flavours, and make the most of in-season produce – so both my blackberry, cinnamon and apple crumble and my gingerbread ice creams are current favourites, fitting perfectly into hotel seasonal menus.

My business ambition has always been to operate my own ice cream parlours as well as wholesale,” continues Steven, “so earlier this year I took over a bigger unit in Greenodd, Ulverston, which has expanded my production capacity and is also open to the public, with click and collect proving extremely popular over lockdown.

To achieve higher output without compromising on quality, Steven bought a Promag Easymix 120 batch pasteuriser from Machinery World, trading in his old machine to mitigate costs.

I bought a second-hand, serviced machine from Machinery World a few years ago, which has worked brilliantly for me, so I went straight to them to talk about my new business requirements,” says Steven. “The great thing about Machinery World is that they sell new and used artisan/batch machines as well as their own ROKK industrial range, so you get a fair trade-in price for your old machine – and they make the process so quick and easy, even at the busiest time of the year.

As well as the comprehensive choice of machines – both refurbished and new – available from Machinery World, the main reason Steven went to them was because he knew he would get an honest recommendation of the right machine for his business expansion.

What I find so refreshing about Machinery World is that they really take time to understand your business needs and what is right for you. Instead of simply trying to sell you something, they give you all the information you need, and let you make the decision yourself,

says Steven.

Everyone at Machinery World is extremely knowledgeable and they are such genuine people, I know that they would give me an honest opinion even if I phoned to ask about a machine from someone else,” he continues. “Mind, you, given the extensive range they stock, I can’t imagine I would need to look elsewhere anyway!

The next challenge for the former pastry chef is to open a second ice cream parlour in a popular lakeside location, so even more customers can enjoy his delicious ice cream.